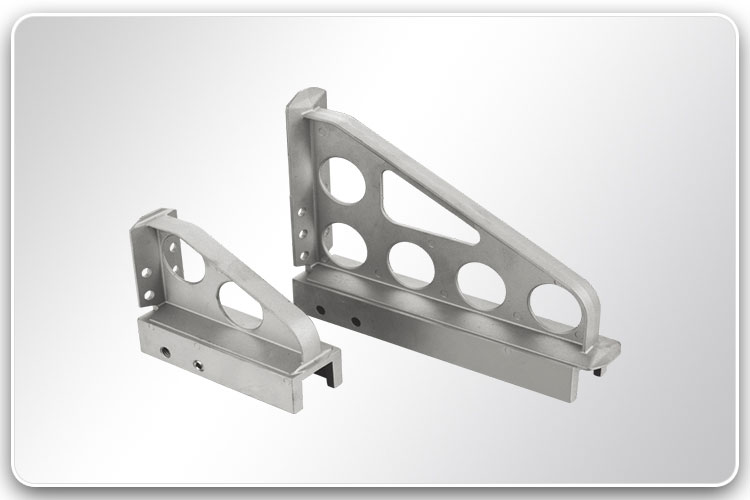

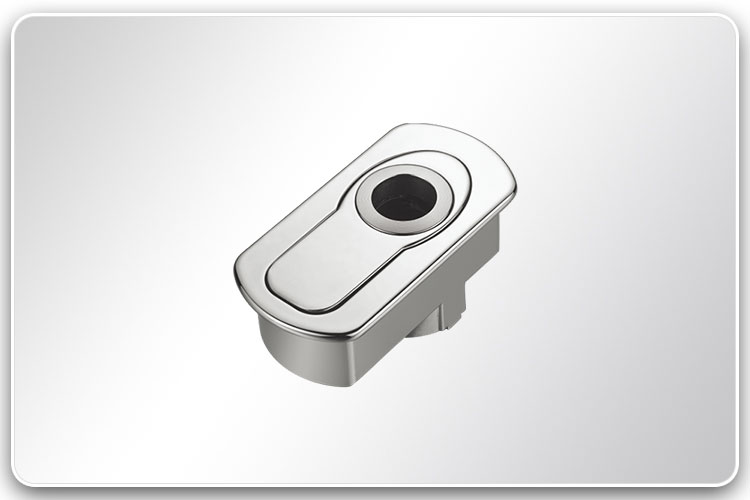

High pressure zinc die casting parts is one of the important product lines

that Auwell co-operated with our manufactures for our worldwide clients. Auwell

manufacture is professional in high pressure zinc die casting parts tooling

development, die-casting, CNC machining, surface treatment and assembling, all

processes are carried out under one roof for high productivity and effective

quality control.

Technical Specifications

-Core elementum Material

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bolster Material: P20,

1.2312, 1.2738

-Standard Components

HASCO, LKM standard or

custom made

-Product popularibus Material

Zamak III, V Zamak, ZA8etc.

-Superficies uber in consummatione

Auwell high pressure zinc

die casting parts surface treatment includes but is not limited to: brush, line

polishing, high gross polishing, mirror polishing, sand blaster, anodizing,

zinc-plating, chrome-plating, nickel-plating, powder coating, silver coating,

E-coat, wet paint, silk screening and stenciling etc.

-Maximum Machining Closing

Force

4,000 tons, pondere partem, 5-30,000g

commoda,

-Usus rich

More than 20 years of

experience in high pressure zinc die casting parts development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Plerumque, providere aquotation in nos operatus III diebus. Combining manufacturingtechnologies et tardus ad facilities, iustus Auwell potest providere samples in V initial weeksfor projects simplex.

-Comprehensive Solution Provider

Cadmiae et summus pressura partes muneris providescomprehensive Auwell moriemini eicientes fromdesigning incipiens, per prototyping, tooling / fixture progressionem, sampling, massproduction et logistics et post-venditionis firmamentum.

-Seu Rigidorum VOL Politiae ipsa QC;

Qualitypolicy animi ex materia gravissima et imperium, et secuta est ad inspectionem finalpre sit amet, cadmiae et summus pressura partes, moriemini eicientes ordines. Materialcertificates includit molendini libellum, 3 pars eget components, andmechanical res tradit, cum RoHS et EMINUS atque tradit super request.Other tradit includit dimensional tradit, crassitudine Superficiem treatment: andsalt nebula test tradit, etc. habemus nostram formare Processus partum O Chartsand ante imperium consilia productio processus QC certum omnibus requisitis ad normam ISO9001-2015 strictisque lacus.

-Payment termino flexibilia

Nam massa productio, weoffer termini solucionis flexibile, rationabile ut fidem verbis data, componat ad clientonly uber quod hi beati sunt; apud eos suscepit. Diu termprojects offerimus ieiunium partus officia vocationis inventarium procul elit.

Cadmiae moriuntur mittentem partibus pressione followingcatalogues in altum productae sunt quae euenire Auwellhas amplissimi orbem elit. Placere clickthe pertinet ad singula imagines. Quaeso consilium, maxime in products arefor modo ad demonstrationem.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик