Description

Stamping is the process of placing flat sheet metal in either blank or

coil form into a torcular calcavitet instrumentum quomorietur surface forms the metal into a net shape. Stamping includes a

variety of sheet-metal manufacturing processes, such as punching using a apparatus torcular or torcular calcavit, blanking, embossing, bending, flanging, and coining.

Stamping could be a single stage operation where every stroke of the press

produces the desired form on the sheet metal part, or could occur through a

series of stages. Progressive morieturs are commonly fed from a coil of steel, from coil

reel to a straightener to level the coil, and then into a feeder which advances

the material into the press and morietur(s) at a predetermined feed length.

Depending on part complexity, the number of stations in the morietur can be varied.

Metalli pretium acre frigido fieri solet, unde progressivestamping, orbem ferri solebat.

For product development, the forming morietur is often developed first, using

laser cutting instead of blanking for trial runs, once the final product meets

the expectation, the blanking morieturs are developed.

Et quis mos in acre, qui potest terunt partes facti sunt ultima post surfacetreatment uber, plerumque tamen eam nisi sit usus in operando pars forproduct ecclesiam.

Normalis in superficiem treatment partes processibus bitur includeelectrophoresis (KTL) et pulvere coating, pingis, et cadmiae plating. Nam elit allsurface praestamus assensum coating, crassitudine caligine conditus volutpat vel aliis expertus fiat petentibus. Anodizing is available for aluminummaterials.

Cubits technical

-material

Mitis ferro: intacta ferro, aeris, aeris et aluminium, et mixturae ferro.

-Machine capacity

1,200 ton hydrau torcular apparatus, quis mos in acre DCCC ton machina, quod ex materia thicknesscan 0.2mm ad 12mm.

Auwell quod per huiusmodi instrumenta designing anddeveloping necesse est quis mos in acre inter processum test gauges massproduction ad QC. Is available for sample dimensional inspectionem CMM reperitur. Superficiem treatment includit KTL et pulvere coating, pingis, et zincplating. PPAP documenta praesto sint ad petitionem.

commoda,

-Rich Experience

Magis quam XX annos experientia in progressionem products andproduction quis mos in acre, praesertim in North American et Europae fora, cum solidum understandingof in materia, et qualis technica signa terrarum.

-Fast Turnaround

Fere, ut in III opus providere a quotation diebus. Combining thelatest technologiae et vestibulum facilities, Auwell fastprototypes potest providere, in II weeks iustus pro projects simplex.

-Solutio in comprehensive Providentem

Auwell provides comprehensive services for stamping projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is

followed through to final pre-shipment inspection. material certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test reports,

etc. We structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Payment termino flexibilia

Tooling payments need to be pre-paid. For mass production, we offer

flexible payment terms, reasonable credit terms will be given, the client only

pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

Applications

Quis mos in acre products industriae et late iam in omnes fere sectorsincluding:

-Aerospace

-Re Rustica

-Ammunitions

-Major appliances

-Small appliances

-Automotive

-commercial

-Construction

-Electronics

-Fire arms

-HVAC

-Lawn care and equipment

-Lighting

-cincinno hardware

-marine

-Medical

-Plumbing

-Power storage

-Power tools

-parvus engine

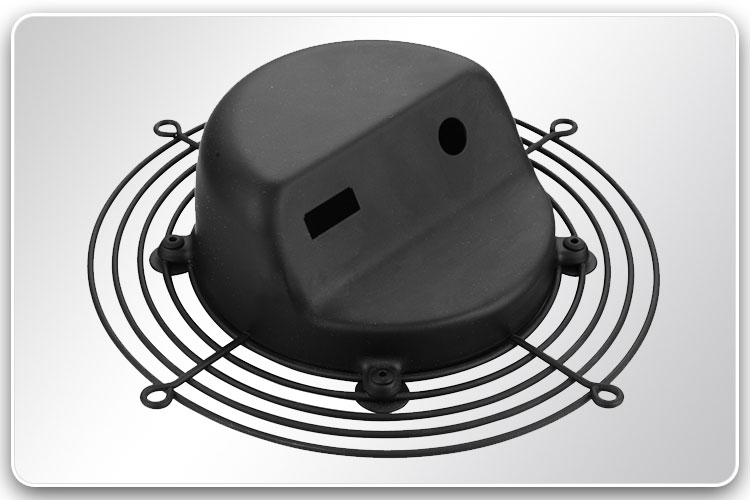

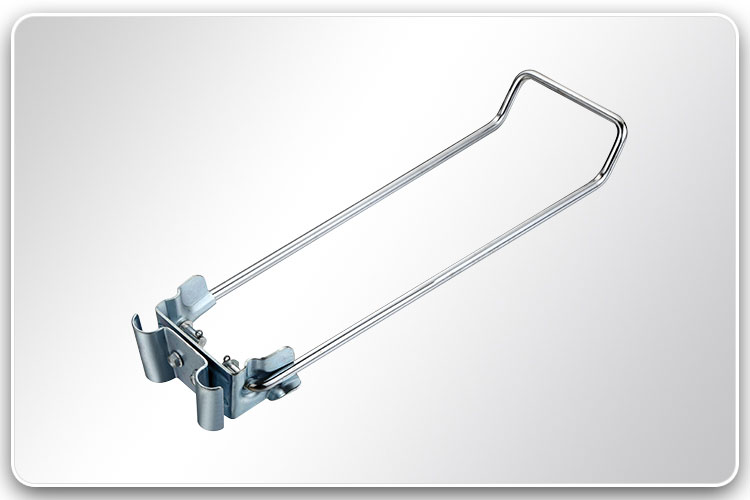

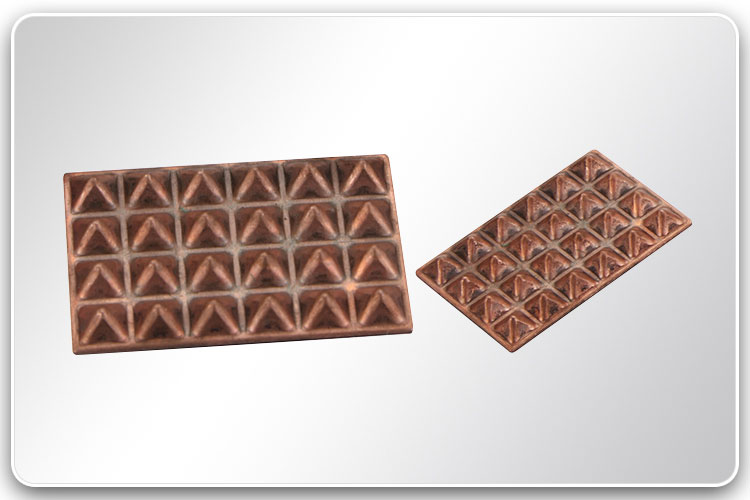

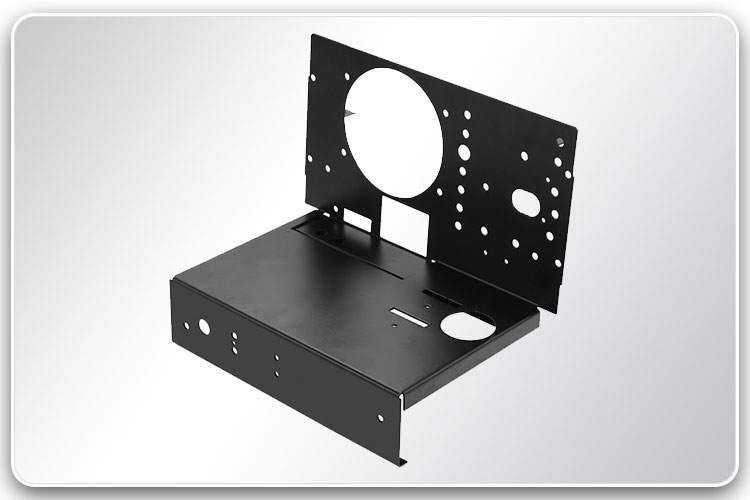

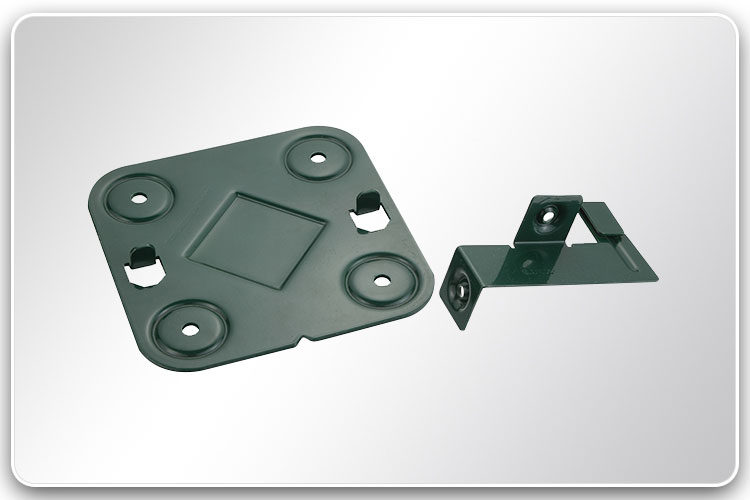

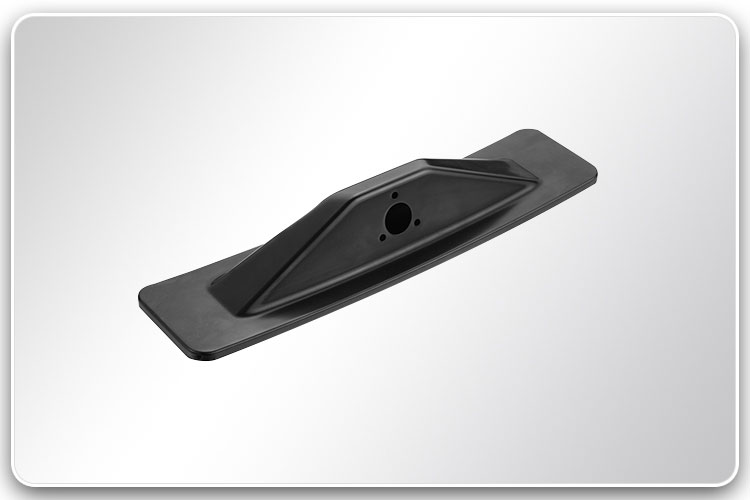

Click following link for browsing of various stamping

products that Auwell has produced and supplied to our distinguished worldwide clients.

Please be advised, most of the products are for demonstration purpose only.

acre partes

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик