Description

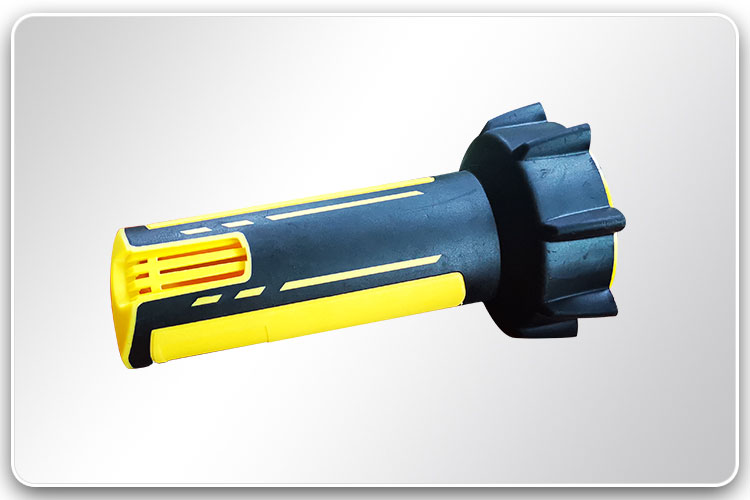

Iniectio Overmolding plastic iniectio auro processus in qua est onematerial (plerumque in TPE) fingitur onto secunda materiales (de more rigidplastic). Si recte et formaturus overmolded TPE dignissim qui tenetur vinculo withthe finem usus elit. Usus est primersor adhesives non requiritur ad consequi optimum ad vinculum inter twomaterials.

Iniectio plastic Overmolding potest ad plures features augendae ofproduct designs, comprehendo

-Vibration damping

-Aequo animo crescat

-Water resistant seal

-Sound absorption

-Nulla Electrical

Two injection molding processes dominate the manufacture of Plastic

Injection Overmolding: insert molding and multi-shot injection molding.

-Insert Molding

Maxime late usedprocess ei coronam aureolam per Plastic Injection Overmolding inserta est, ibi est positus in a pre-moldedinsert TPE fingunt, et est recta super exortum est. Theadvantage inserta est corona per singula iaculat est, quod conventional IM machinis possit beused (Nova machinery Sumptus necessaria sunt), et cum tooling costsassociated inserta sunt illi labium minus quam multi-iecit in processus.

-Material multa CUMATIUM

Multiple material, also known as two-shot (or multi-shot) Plastic

Injection Overmolding process, molding requires a special injection molding

machine that is equipped with two or more barrels, allowing two (or more)

materials to be shot into the same mold during the same molding cycle. A molder

will choose multi-shot molding to reduce cycle times, achieve superior part quality

and reduce labor costs.

Nam Plastic Injection Overmolding lectio processus in generali, insertmolding annui productionem, cum sit electionis processum de Tempore ac de loci humilis laborcosts sunt. Nam superiore volumine productio progressio (unitsannually super 250,000), vel de locis auctus labor costs, multi-iecit operationsare ei coronam aureolam per modum electionis.

Et dedi ei coronam aureolam Auwell inserta et multi injectionovermolding processus plastic materiam ad clientsâ optio.

commoda,

-Rich Experience

Magis quam XX annis ofexperience in Plastic Injection Overmolding et partproduction productum progressionem, praesertim in North American et Europae fora, cum solidum understandingof in materia, et qualis technica signa terrarum.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to deliver first sample in 6 weeks.

-Solutio in comprehensive Providentem

Plastic Injection Overmolding Auwell providescomprehensive servicia pro projects fromdesigning incipiens, per prototyping, tooling / fixture progressionem, sampling, massproduction et logistics et post-venditionis firmamentum.

-Seu Rigidorum VOL Politiae ipsa QC;

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Plastic Injection Overmolding orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Payment termino flexibilia

Nam tooling, generalpayment est terminus est L% -50%, quod est depositum% L, L% Post primum specimenque libero. Formass productio, si termini solucionis offer flexibilior, rationabile willbe credit verbis datum, quod non dat quod hi beati sunt; client cum theyreceived uber. Longa-term projects pro nobis offerre pro muneris vocatio-off inventory fastdelivery requisita.

Related Products

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Plastic partes Thermoforming

Plastic partes Thermoforming

Rubber & Silicone Molding

Rubber & Silicone Molding

Iniectio partes sequentes catalogi dignissim arethe Auwell quae protulit amplissimi worldwideclients suppleverunt. Please click in imaginibus pertinet ad singula. Quaeso consilium, maxime in products sunt enim modo ad demonstrationem.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик