Description

Tooling Modelsâ tantum portus, directe partes Plastic Injection suppleret id est unum de key ad exemplar negotiis s Auwellâ plastic iniectio auro servicia.

Unlike the“Tooling Only Models”, the mold structure, material, hardness, standard parts are all must be in accordance with the design, for plastic injection parts business model, Auwell is responsible for the final plastic injection parts, make sure the parts quality meet the client’s specifications and requirements. Auwell is free to design the tooling structure based on our own technology and machines.

For this business model, once the client pays the tooling cost, Auwell will be responsible for tooling maintenance and replacement for the entire product lifetime. This model is preferred for small sizes and precise plastic injection parts.

Fere enim plastic iniectio partes negotium exemplar si clientum ad navis formam vel derivare tooling alio amet, non confirmat forma operatur proprie alius apparatus alias armorum et proportio progressionem fingunt ad fingunt releasing pretium sit amet, ante.

Cubits technical

-Material

Post plasticmaterial available pro nobis plastic iniectio auro confinia:

Ø PA 6/6 | Polyamide 6/6: Compositio: Nylon 6/6

Ø PARA | Polyaryl Amide

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT, DELICIAE | Polybutylene Terephthalate Polyethylene Terephthalate,

Ø PC | Polycarbonate

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø PC-PET | Polycarbonate-Polyethylene Terephthalate

Ø Princ | Polycyclohexylenedimethylene Terephthalate

Ø PE | Polyethylene

Ø PE-P | Polypropylene polyethylene,

Ø PE-PS | Polyethylene-Polystyrene

Ø PEBA | Acta Polyether Amide

Ø PEEK | Aether Polyether Ketone

Ø PEI | Polyetherimide, Vivamus neque

Ø PES | Polyether Sulfone

Ø DELICIAE | Terephthalate polyethylene, Rynite

Ø PLA | Polylactic Acid

Ø PMMA | Polymethyl Methacrylate, Acrylic

Ø POM | Acetal Polyoxymethylene, id mauris

Ø P | Polypropylene

Ø PPA | Polyphthalamide

Ø PPS | Polyphenylene Sulfide, Ryton

Ø PS | polystyrene

Ø PS-PPE | Polystyrene, Polyphenyl atmosphaeris aethereis, Vivamus neque

Ø PSU | Polysulfone, Udel

Ø PVC | Polyvinyl Chloride (Shore D)

Ø pvdf | Fluoride Polyvinylidene

Ø SAN | Styrene Acrylonitrile

Ø TPO | Thermoplastic Polyolefin

Ø TPU | Thermoplastic Polyurethane (shore D)

Ø Custom-sourced Resin

-Moldbase

LKM ducuntur, HASCO, 1,1730, S50C, S55C, ML, MLV

-Active Elements

Ø P20, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, H11, H13, 420

Ø ASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star(A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Mould Surface

Photo Criofractura, erodestructure ducens Blaster linea expolitio magna crassa expolitio, mirrorPolishing.

-Machines: 100-3,000 ton

closing force

commoda,

-Usus rich

Magis quam XX annos experientia in plastic iniectio progressus partes et productio parte, praecipue ad fora Europae et American North, ad solidum ex materia intellectus, et qualis technica signa terrarum.

-Fast Turnaround

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell is able deliver first sample in 4 weeks.

-Comprehensive Solution Provider

Comprehensive servicia progressio et providet Auwell partes incipiens a plastic iniectio navigare cogitans, et per prototyping, tooling / fixture progressionem, sampling, massa productio et logistics et post-venditionis firmamentum.

-Seu Rigidorum VOL Politiae ipsa QC;

Qualis animi consilium a materia gravissima et imperium, et secuta est ad ultima pre-plastic iniectio ad inspectionem sit amet partibus ordines. Libellum materiales testimonium includit molendini, 3 pars eget components, et mechanica res tradit, cum RoHS et EMINUS atque ad petitionem tradit. Nostram formare non processus partum cogitationes fluunt et Imperium charts ante productionem processus QC certum omnibus requisitis ISO9001-2015 ducendi secundum speciem.

-Payment termino flexibilia

For tooling, the general payment term is 50%-50%, meant 50% deposit, 509% after first sample free. For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Applications

-Plastic injection molding

products have widely been used in almost all industrial sectors

including:

-Aerospace et tutamen

-Automotive

-Agriculture Machinery

-Energy

-Electronics

-construction

-Transportation

-Industrial

-Consumer Products

Related Products

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Iniectio plastic Overmolding

Iniectio plastic Overmolding

Plastic partes Thermoforming

Plastic partes Thermoforming

Silicone Flexilis & Auro

Silicone Flexilis & Auro

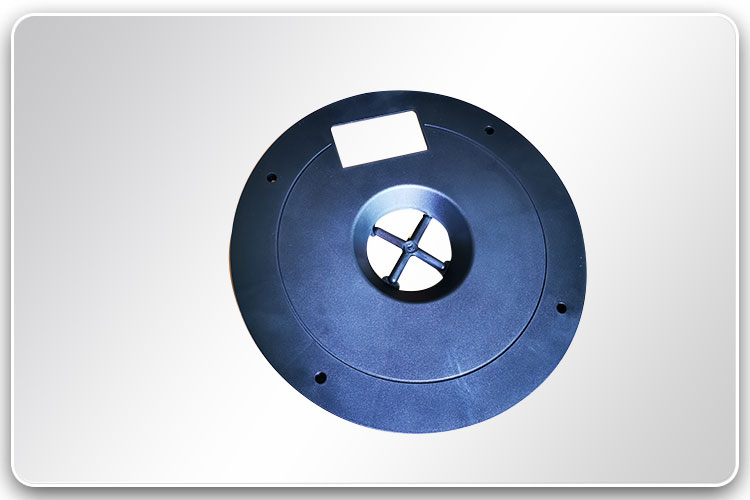

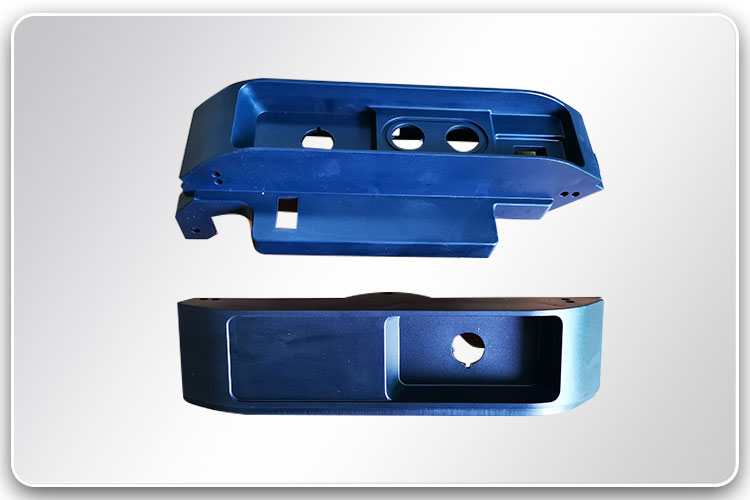

Iniectio partes sequentes catalogi dignissim arethe Auwell quae protulit amplissimi worldwideclients suppleverunt. Please click in imaginibus pertinet ad singula. Quaeso consilium, maxime in products sunt enim modo ad demonstrationem.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик