Description

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow

cavity of the desired shape, and then allowed to solidify. The solidified part

is also known as a casting, which is ejected or broken out of the mold to

complete the process.

Aluminium fusura proiecta es super discursum plerumque ferri metallis. Sed alia quaedam metalla transcurrit, ut intacta ferro, mixturae ferro, et aereos, aeris, magnesii, et cadmiae, quae etiam ad producendum per foundries castings.

Casting is most commonly used for making complex shapes that would be

difficult or uneconomical to make via other methods. The casting process

typically includes 4 steps - cutting, forming, assembling, and surface

treatment.

-facta fingunt

In casting processus, forma enim in figura partim ex desideravit. Simplex consilium potest madein unum solidum pars aut forma, mutuatas. Magis designs sunt universa in duas partes, split dicuntur exemplaria. Est instar cerae ligna plastic ormetal. Secundum diversos processus onthe formas per species construuntur fornace metallum casted ad numerum partium produci amissio magnitudine et multiplicitate amissio.

-ignis mollibus

Ina fornacem ignis mollibus fit. De crimen in processus conflans includes: levis erit hujusce desolati sunt: et liber adjustingthe desolati sunt: et percussoque in naues onerariae comprensae. Fit ab igne liberavit pessimas vapores metalto vitare sordes vitiorum elementa.

-Pouring

In a foundry, molten

metal is poured into molds. Pouring can be accomplished with gravity, or it may be assisted with a

vacuum or pressurized gas.

- Shakeout

Is, quae coierant metalcomponent tunc de locis suis fingunt. Ubi est qui fingunt harenae-fundatur, fieri non sciri quo concutiendo, vel ruere praedixi.

-Degating

Degating is the removal

of the heads, runners, gates, and risers from the casting. Runners, gates, and risers may be removed

using cutting torches, bandsaws, or ceramic cutoff blades.

-calor autem tractans

Heat treating is a group

of industrial and metalworking processes used to alter the physical, and

sometimes chemical, properties of a material.

-Surfacecleaning

Et post degating heattreatment, ut harenae aut alia media remain colligata est casting ei coronam aureolam. Toremove fingunt quid reliquiae, et vento urente, et superficies est lautus usura a clean process.Numerous materiae potest esse in cast superficiebus, inter ferro, ferro, alterum metallum alloys, oxides, aluminium, vitreis globulis iuglandium nucum putaminibus, pistoria pulveris et multis aliis.

-summam

The final step in the

process of casting usually involves grinding, sanding, or machining the component to achieve the desired dimensional accuracies,

physical shape, and surface finish.

Cubits technical

-Quia materia casting

Ferrum, mitis ferro: alloysteel: intacta ferro, aluminium, aeris, aeris et cadmiae.

-Following processes are available for producing casting parts upon the

nature of the design.

ØSand casting — Green or resin bonded sand mold.

ØExempla iaciens spuma excidisset polystyrene tellus harena mixta fingunt.

ØInvestment casting — Wax or similar sacrificial pattern with a ceramic mold.

ØForma emplastri forma telorum tellus.

ØV processum mittentes vacuo thermoformed dignissim arenam formam fingit. Non humorem, testa resinamve lentescit requiritur.

ØDie jactum metallo forma.

ØBillet (ingot) casting — Simple mold for producing ingots of metal, normally for use in other foundries.

Except providing our clients with casting parts, most

of products Auwell supplies with further machining and surface treatment

service.

Forging is a manufacturing process involving the shaping of metal using

localized compressive forces. Generally, Auwell does not offer forging, but only

using forged parts as pre-material for further processing.

Advantages

-Usus rich

More than 20 years of

experience in casting products development and production, especially to the

European and North American markets, with solid understanding of the material,

technical and quality standards worldwide.

-Fast Turnaround

Plerumque, providere aquotation in nos operatus III diebus. Combining manufacturingtechnologies et tardus ad facilities, iustus Auwell potest providere, in II ieiunium prototypes weeksfor projects simplex.

-Solutio in comprehensive Providentem

Auwell provides

comprehensive services for casting projects starting from designing, through

prototyping, tooling/fixture development, sampling, mass production, and to logistic

and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. For quality control of casting parts, we provide set

of test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Payment termino flexibilia

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Applications

Fabulae late fusis products sunt fere sunt usus apud comprehendo allindustrial aer discrimina accipit:

-Aerospace et tutamen

- Automotive

- Agriculture Machinery

-Energy

- Electronics

- Construction

- Transportation

- Industrial

-Consumer Products

Sequenti autem catalogi theones quam fundendi Auwell produxerit fructus amplissimi worldwideclients suppleverunt. Please click in imaginibus pertinet ad singula. Quaeso consilium, maxime in products sunt enim modo ad demonstrationem.

Tractatus Aliquam Steel mittentem

Tractatus Aliquam Steel mittentem

Aliquam Steel colle enim Casting

Aliquam Steel colle enim Casting

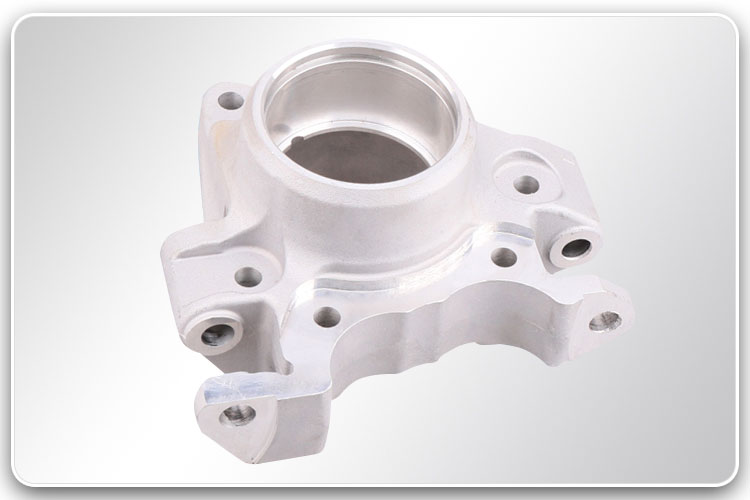

steering Knuckle

steering Knuckle

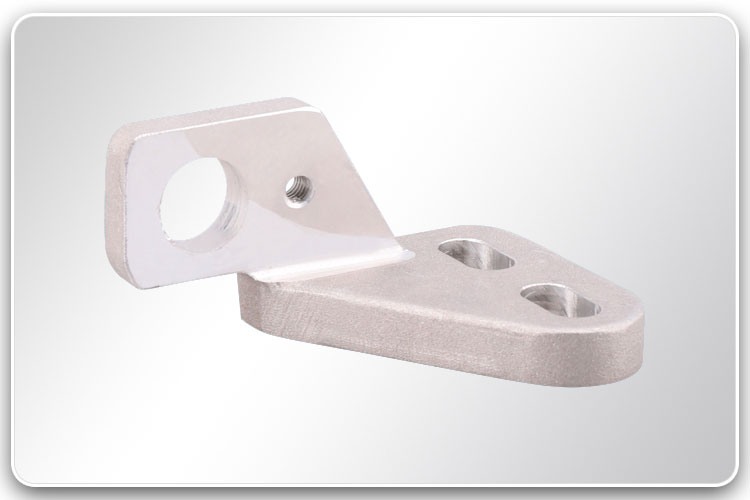

Forging Spline Connector

Forging Spline Connector

Martianus Rota cudendum Hub

Martianus Rota cudendum Hub

Aluminium base AGV

Aluminium base AGV

Alu. Arena & gravitatis mittentem

Alu. Arena & gravitatis mittentem

Brass Gravity& Sand Casting

Brass Gravity& Sand Casting

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик