Description

Alta tractus est formatam sheet metallum processus usus ad industrially producecup informes buxum informibus, et alia universa cavae-curvam informibus sheet partes. Theprocess altum gignit, et seamless per species a sheet metallum. In deepdrawing, inanis est cedulam metallum radiatim trahi faciunt actionem morietur themechanical ferrum. Mutatione figurae sic processus withmaterial retentio. Processus attenditur "abyssus" quae trahit ex parte qua excedit thedepth diam.

There are 4 steps for deep drawing process:

-secans Blanks

The deep drawing process

starts from a flat disc that blanked from a steel sheet. Auwell improves

material utilization by staggering our blanks to reduce scrap and material

costs. The deep drawing process minimizes waste, optimizing the efficiency of

material usage.

-Starting Cup

Prima die truncatisque blankat statione circa vestis quae misisti ad mori faciendum naribus ferrum andpressed confirmat. Facientes operationem virtutis increasesthe alta trahit prima operis pars per caecitatem.

-Keep Drawing

Depending on your desired

length-to-diameter ratio, Auwell will design dies with several draws to create

the basic shape of your deep drawing parts. The forces produced in the deep drawing

process naturally cause the shell wall to thin out, while the shell flange

thickens at each stage. Our professional team designs the die to stretch the

metal as evenly as possible into the part’s desired shape.

-Post-Drawing Process

After obtaining the

desired shape of the product, the following process can be assembled to other

components or as semi-finished products for future processes including

deburring and surface treatment including polishing, zinc-plating, nickel

plating, chormating, powder coating, painting, etc.

The Benefits of Deep Drawing process

-Speed

S fere methodo itâ mostefficient ordines copiosissimum

-Eliminates assembly

steps.

TRACTUS producesshapes clausis solet desinit. Hoc opus ad interficiam et CONFERRUMINO multiplepieces vitat.

-Seamless

A deep drawing can or

tube shape has no joins. This makes deep drawing an ideal process for anything

that needs to be water or air-tight.

-princeps accurate

Parts coming off a

forming press are extremely repeatable. If the die was made correctly, they’ll

also conform very closely to the drawing.

-Complexgeometries ipsius fit.

Deep drawing can produce

complex parts like an oil pan for an engine or complex filter housings.

-Frugum strongparts

Tot metallorum hardenas opus, quod formosum. Per se, vitreisque structuram concedit quaedam moles ofmovement autem supra quod Quae quidem est clausum. Sub alta ducendo alot deformationis metallis, ex partibus lenta perfecta virtus altissimi.

Auwell is capable of designing and developing necessary tooling for deep

drawing production. CMM is available for sample dimensional inspection. Surface

treatment includes KTL, powder coating, painting, zinc plating. PPAP documents

are available upon request.

Cubits technical

-Materials

Mild steel, stainless

steel, copper, brass, aluminum, and alloy steel.

-Machine capacity

1,200-ton hydraulic press

machine, 800-ton stamping machine.

Thickness ranged from

0.2mm to 6mm.

Advantages

Our deep drawing

parts offer numerous advantages over traditionally machined, cast, or molded

parts. We can reverse-engineer existing components, and can often combine

multiple parts into a single stamped piece. The advantages of deep drawing

process are:

-redigendum costs

-Reduce waste

-Lower assembly cost and

time

-Partibus perfectum efficiunt fortiora metalli structureto condimentum.

Besides the

technical advantages of deep drawing process, the competitive advantages of

working with Auwell are:

-Usus rich

More than 20 years of

experience in deep drawing products development and production, especially to

the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Plerumque, providere aquotation in nos operatus III diebus. Combining manufacturingtechnologies et tardus ad facilities, iustus Auwell potest providere, in II ieiunium prototypes weeksfor projects simplex.

-Comprehensive Solution Provider

Alta tractus in officiis Auwell providescomprehensive projects incipiens a navigare cogitans, et per prototyping, tooling / fixture progressionem, sampling, massa productio et logistics et post-venditionis firmamentum.

-Rigid QC Policies

Qualitypolicy animi ex materia gravissima et imperium, et secuta est ad inspectionem finalpre-amet. Libellum materiales testimonium includit molendini, 3 pars eget components, et mechanica res tradit, tum ad petitionem RoHSand SPATIUM tradit. Alii tradit includit dimensional tradit, crassitudine surfacetreatment: et sal nebula test tradit, etc. structuram Nos ourprocesses partum dissipantur cogitationes fluunt et Imperium apud charts productio, processus pluris aestimantur QC makingsure omnibus requisitis ad normam ISO9001-2015 anddrawing cubits.

-Payment termino flexibilia

Tooling liberate egent actione damni praeexistunt secundum solvit. Massa productio offerimus pretium elit terminorum reasonablecredit terminis dabitur nisi componat cum cliens theproduct laetus accepit. Diu terminus consiliorum vocem laudis fuistis inventoryservices ieiunium partus requisita.

Applications

Sheet metallum fabricam late products sunt fere sunt usus apud comprehendo allindustrial aer discrimina accipit:

-Aerospace et tutamen

-Music

-Energy

-Electronics

-Construction

-Transportation

-Industrial

-Consumer Products

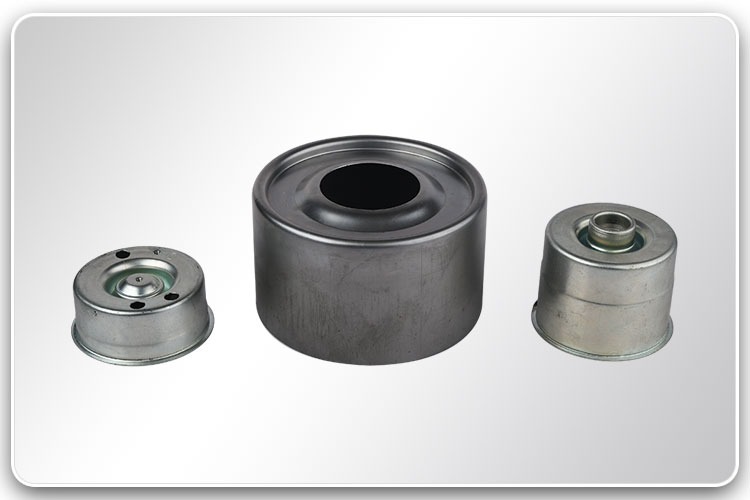

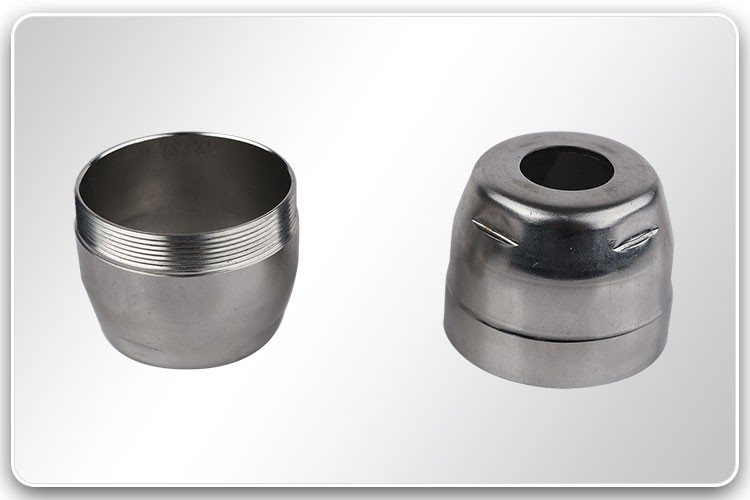

The

following catalogues of deep drawing products are the ones which Auwell has

produced and supplied to our distinguished worldwide clients. Click following

pictures for details. Please be advised, most of the products are for demonstration

purpose only.

Tractus Spinning alta &

Tractus Spinning alta &

Porta elevator Pulley

Porta elevator Pulley

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик