Deep drawing & spinning is actually a supplementary manufacturing

process to stamping. When products with cup-shaped, box-shaped, and other

complex-curved hollow-shaped that are not able to formed by stamping process,

or, when the depth of the drawn parts exceeds its diameter, deep drawing and

spinning might be the right manufacturing process.

Alta tractus & materiam esse humilis in spheara processrequires chalybe magna distantia, quia excellentforming perficientur. Ita, humilis chalybe optionem esset optimus, atque obviouslyaluminum materia aeris est bonum hoc processus. Aliquam ferro an optio sit couldalso in altum processum, sed ut requirere heattreatment drawing & valde coram insinuatione mollire summopere materiam proximam processus.

Et surfacetreatment in altum drawing spheara & possunt esse partes:

-Polishing

-Cadmiae-plating

-Nickel plating

-chrome plating

-Silver plating

-KTL

-Hot dip galvanization

-pingis

-Powder coating

-anodizing

Auwell habet XX annis altum prae drawing spheara & partium progressum et productio. S Auwellâ experientia dives sit amet effective, fastturnaround magnum et altum productio facultatem quoque, ut fortunae mercedem termhas lucratus fama de clients.

Competitive Advantages

-Usus rich

More than 20 years of experience in deep drawing & spinning parts

development and production, especially to the European and North American

markets, with solid understanding of the material, technical and quality

standards worldwide.

-Fast Turnaround

Fere, ut in III opus providere a quotation diebus. Combining thelatest technologiae et vestibulum facilities, Auwell potest providere fastprototypes in altum valde drawing & partes II weeks iustus pro projects simplex.

-Comprehensive Solution Provider

Auwell provides comprehensive services for deep drawing & spinning parts

development starting from designing, through prototyping, tooling/fixture

development, sampling, mass production, and to logistic and post-sale support.

-Seu Rigidorum VOL Politiae ipsa QC;

Qualis animi consilium a materia gravissima et potestas et isfollowed ad inspectionem ultima pre-amet. Libellum materiales certificatesinclude molendini, 3 pars eget components, et mechanicalproperty tradit, cum RoHS et EMINUS atque ad petitionem tradit. Alii reportsinclude dimensional tradit, crassitudine Superficiem treatment: et sal nebula testreports, etc. habemus nostram formare Processus partum O charts et Imperium Plansbefore productio, processus pluris facis ut cuncta ex ipsa QC; et quia withISO9001-2015 drawing cubits.

-Flexible Payment Term

Tooling liberate, necesse est earn solvit. Nam massa productio, si termini solucionis offerflexible, rationabile verbis fidei et data sit in onlypays client cum sunt beati per productum accepit. Diu termprojects offerimus ieiunium partus officia vocationis inventarium procul elit.

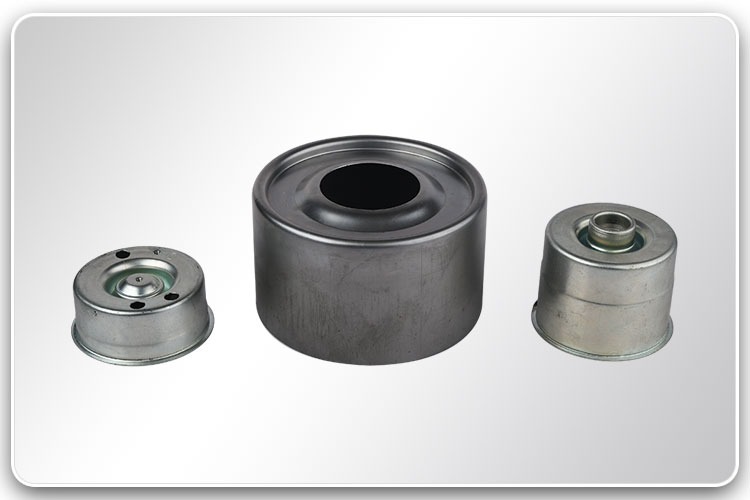

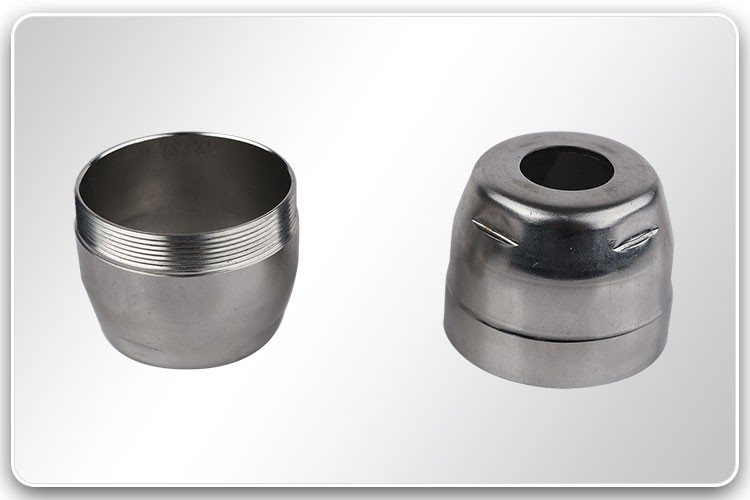

The deep drawing & spinning parts display on this section are some of

the products Auwell has developed for our clients, all of the stamping parts

are OEM made, following products are only for demonstration purpose. If the

clients have the deep drawing & spinning parts need to be developed, it is

warmly welcome to contact us for details.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик