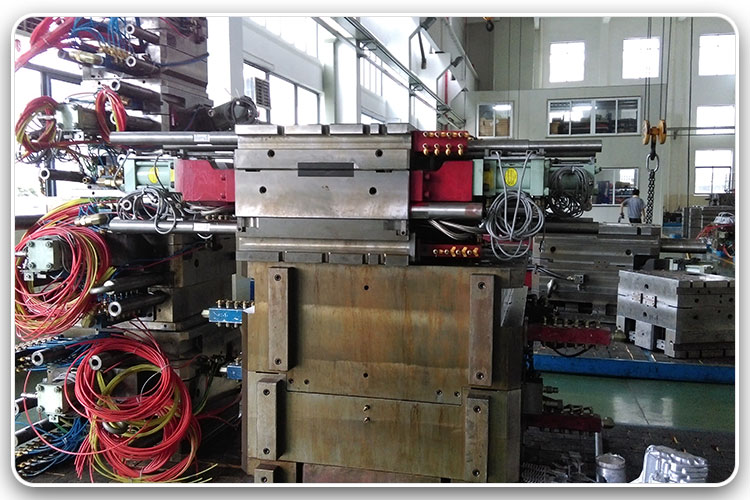

Ningbo is one the most famous high pressure die casting

tooling industry cluster in the world. Auwell co-operates with reliable and

long-term based partners, export tools to worldwide market. We also offer final

products that made by die casting, machining, surface treatment and assembling.

High pressura casting tooling constructione praestat mori, et thefinal productum est diversis negotiis modus. Nam termini producti andmanufacturing tribuit, pertinet ad rationem termini producti Auwell, premit altum die jactum tooling wehave consilio et libertate machiningfixtures. Sed quia princeps pressura mori casting tooling negotiis, et providere normallythe clients tooling consilio, inter omnes components drawingswith cubits omnibus necessitatibus, etiam corporeis, duritia robora vincis, thebrand vexillum in partibus utendum est etc., omnibus scilicet detailed requirementsare et mundabitur sanctuarium. Quidam clients ut quodcumque petierit a Auwell providere acomplete sarcina fundatur super illis, et ex parte drawings machina imaginum.

Auwell dives experientia est princeps pressura in alea ordinatione castingtooling: faciens, praesertim in foro EU. Et fecit nos suppliermouldbase ex clientsâ cubits.

Cubits technical

-Core elementum Material

H13, 1.2344 (X40CRMoV51), 1.2367 (X38CrMoV5-1) H11, 1.2343 (X38CrMoV5-1)

Bolster Material: P20,

1.2312, 1.2738

-Standard Components

HASCO, LKM ducuntur factus vexillum orcustom

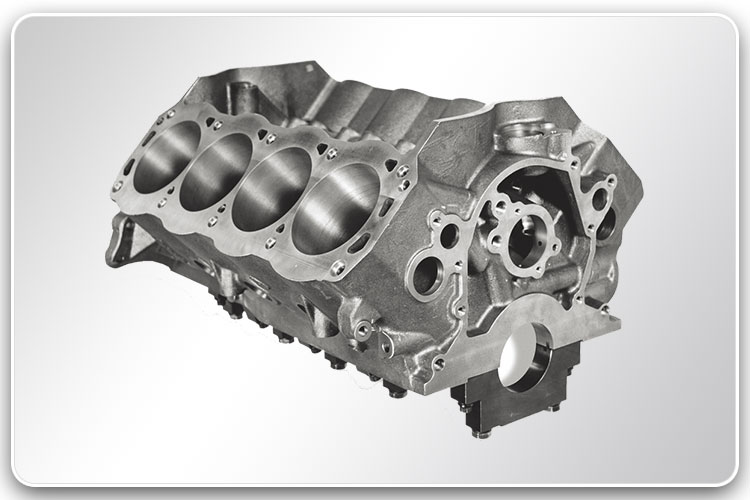

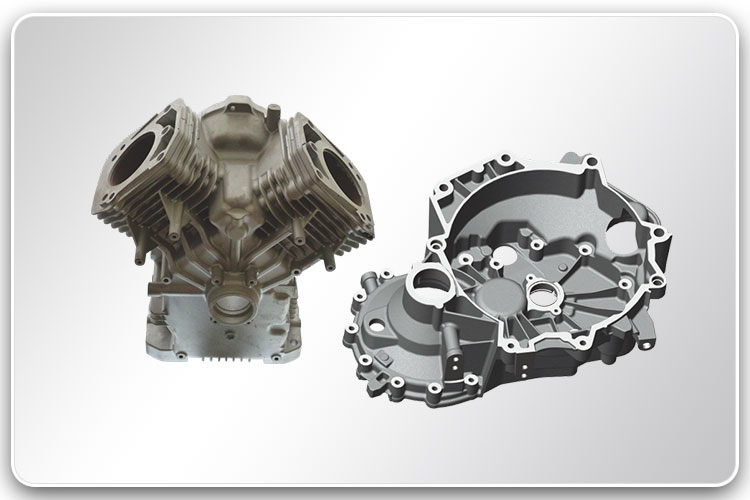

-Product popularibus Material

AL226, AL230, AlSi10Mg, A360,

A380, A413 and A304 K-alloy, ADC12, ADC10 etc.

-Maximum Machining Closing

Force

4,000 tons, pondere partem, 5-30,000g

Advantages

-Usus rich

More than 20 years of

experience in high pressure die casting tooling development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide initial samples in just 5 weeks

for simple projects.

-Solutio in comprehensive Providentem

Auwell provides

comprehensive services for high pressure die casting tooling starting from

designing, tooling and fixture manufacturing, tooling test shot and to logistic

and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to high pressure die casting tooling orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request.

Other reports include dimensional reports, surface treatment thickness, and

salt fog test reports, etc. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

The following catalogues of high pressure die casting tooling are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, these products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик