Description

Rubber & Silicone molding is a manufacturing process whereby an amount

of uncured rubber or silicone is transformed into a usable product.

There are 3 types of Rubber & Silicone molding process:

-Rubber compression molding

Placing a predetermined

amount of rubber compound directly into the mold cavity and then compressing it

into the shape of the cavity by closing the two sides of the mold.

-Flexilis iniectio auro

Purgamentum Silicone & in hac illi labium infectam Flexilis compositis processus calescit ad liquidstate quod infusum est in conspectu fingunt. Quod productum est, et dimisit a themold claudendo foramen illud infusum altera accipere.

-Flexilis translatio alteram coronam auream

During this Rubber &

Silicone molding process the uncured rubber or silicon compound is placed in a

part of the mold called a “pot” before being forced through an aperture into a

cavity in the shape of the desired product. When cured, the mold is split

releasing the final product.

Material from Auwell for Rubber & Silicone molding:

-N nitrile et Buna,

The most popular and

low-cost solution in Rubber & Silicone molding

-Hydrogenated Nitrile

This is a more expensive

hydrogenated variation of Nitrile polymer, which increases its resistance to

heat, petroleum products, and ozone almost fivefold.

-Ethylene Propylene DieneMonomer (EPDM)

Commonly used in rubber

molded products for steam systems, vehicles panel seals, and braking systems

due to its high resistance to brake fluid

-Silicone

Obsistens tohigh et nuditate humilis temperaturis, habet quod sit flexibile ad bonum tempestas resistentia.

-Fluorosilicone

Temperaturerange componit commoda cum vi resistentiae coniunctas silicone oleum, cibus, ac per solventsfound fluorocarbons.

-Neoprene

Sicut multi-purposematerial fortis est, ut possit usus est numerus Flexilis solutions ei coronam aureolam. Abrasione obsistens proprietates ignis et frequenter eum in hasgood themanufacture missa et vehicula transitus apparatu

-naturalis Purgamentum

Aliquam a iuvantis arbor ex natura productproduced

-SBR (Styrene butadiene)

One of the more

cost-effective polymers that can be used in rubber molding and is frequently

used in the production of tires, diaphragms, seals and gaskets and the mass

production of other rubber parts

-fluorocarbon

This relatively expensive

rubber compound combines a wide range of chemical resistance and

high-temperature properties.

-Butyl

Has a high resistance to

gas permeability. This makes it the ideal solution in the production of seals

for high-pressure gas and vacuum systems

-Urethane

A fairly high priced, but

commonly used material in applications subject to high pressure and constant

shock loads

Advantages

-Rich Experience

More than 20 years of

experience in Rubber & Silicone molding parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 5

working days, for simple and small size tooling, we are able to deliver first

sample in 2 weeks.

-Comprehensive Solution Provider

Purgamentum Silicone ei coronam aureolam per officia providescomprehensive Auwell & ex partibus developmentstarting navigare cogitans, et per prototyping, tooling / fixture progressionem, sampling, massa productio et logistics et post-venditionis firmamentum.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Rubber & Silicone molding parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Flexible Payment Term

Nam tooling, generalpayment est terminus est L% -50%, quod est depositum% L, L% Post primum specimenque libero. Formass productio, si termini solucionis offer flexibilior, rationabile willbe credit verbis datum, quod non dat quod hi beati sunt; client cum theyreceived uber. Longa-term projects pro nobis offerre pro muneris vocatio-off inventory fastdelivery requisita.

Related Products

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Iniectio plastic partes

Iniectio plastic partes

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic Thermoforming Parts

Plastic Thermoforming Parts

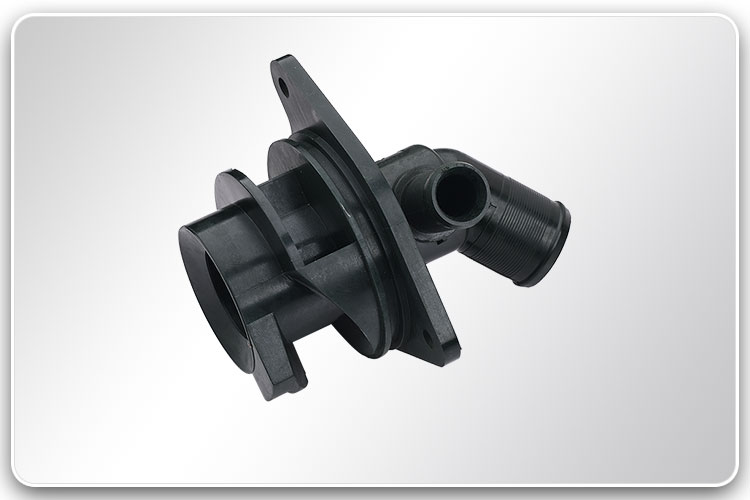

The following catalogues of Rubber & Silicone molding parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик