Descriptiotion

Fingere cedulam metallum metallum processu formationis partium producentibus p. Sheet metallum processus fabricam highly producendum diuturna eget components tam conveniens est ad utrumque finem prototypes et productio usu. Darent operam et sumptus-efficens moris cedulam metallum in- requiro pro solutione vestibulum elit. Fabricationis servicia range de volumine, humilis volumine prototyping ad productionem fugit cum summus sumptus peculi significant.

Typically includit processus in gradibus IV - secantibus praestricta formatam conveniunt, et superficies treatment.

-Processus CAESUS

We offer various cutting options with thickness ranged from 1mm to 150mm, this includes oxygen cutting with a maximum thickness capacity of 150mm for carbon steel. We also offer plasma cutting, laser cutting, water jet cutting, wire cutting, shearing, and/or die-cutting, we may also use punching for holes. Laser cutting is the preferred option for cutting sheets, it’s speed and precision guarantees spectacular results. With thicker materials, plasma cutting may be favorable for it’s speed. This method is normally used when the material thickness is over 10mm.

-Processus formatam

Processu formationis proprie includit oscula Hidrauliskās formatum instare ferro punguntur et milling. Usi consilio partsâ determinat naturam. Essential procedure Deburring est apud Vicifontem et imperati conveniunt.

-et congregans

For sheet metal fabrication, the main process of assembling is welding. Fixtures need to be pre-designed and made to ensure a productpostquam nihil corruptionis Vicifontem. Quibusdam locis ubi convenissent milling requirit. A pre-paro of test gauges sunt developed per inspectionem species, et completum cursus functionality et opus.

-Superficiem treatment

Superficiem treatment processus est normalis ad fabricam sheet metallum products includit electrophoresis (KTL) et pulvere coating, pingis, et cadmiae plating. Sicut enim magna products gb, cum pictura est late usus est in medio partium magnitudine, et KTL processus esse malebat.

For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request.

Anodizing is available with aluminum materials.

Technical Specifications

-material

Mitis ferro: intacta ferro, aeris, aeris et aluminium, et mixturae ferro.

-facultatem machina

1,200 ton hydrau torcular apparatus, quis mos in acre DCCC ton apparatus, materia crassitudine amputatis testiculis et oxygeni ad 150mm planta processerint, 60mm pro plasma amputatis testiculis et 25mm pro laser comedat. Maximum ex parte magnitudinis: * 1,500mm 2,000

-alii cubits

Et per huiusmodi intelligibiles designing necessaria developing sheet metallum instrumenta ad fabricam inter formatam perit, fixtures pro welding est, et massa productio test gauges ad QC. Is available for sample dimensional inspectionem CMM reperitur. Superficiem treatment includit KTL et pulvere coating, pingis (Walspar), et cadmiae plating. PPAP documenta praesto sint ad petitionem.

Advantages

-Usus rich

Magis quam XX annos experientia in fabricatione sheet metallum products productionem et progressionem, praesertim in North American et Europae fora, per solidum in materia intellectus, et qualis technica signa terrarum.

-Fast Turnaround

Fere, ut in III opus providere a quotation diebus. Coniunctis tardus technologies et vestibulum facilities, providebit ieiunium Auwell potest prototypes in II weeks iustus pro projects simplex.

-Comprehensive Solution Provider

Fabricationis servicia pro projects incipiens a sheet metallum Auwell praebet comprehensive navigare cogitans, et per prototyping, tooling / fixture progressionem, sampling, massa productio et logistics et post-venditionis firmamentum.

-Rigid QC Policies

Qualis animi consilium a materia gravissima et imperium, et secuta est ad inspectionem ultima pre-amet.

material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Payment termino flexibilia

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Applications

Et est late usus est in fabricatione sheet metallum products industriae sectores inter omnes fere,

-Aerospace and defense

-Music

-Latina Apparatus

-Energy

-Electronics

-Construction

-translationem

-Industrial

-Consumer Products

De his autem catalogs sheet metallum ones, quae sunt products commentum, suppleverunt Auwell habet et produci ad distinguished terrarum clients. Please click in imaginibus pertinet ad singula. Quaeso consilium, maxime in products sunt ad demonstrandum nostrum capability ad sola manufacturing.

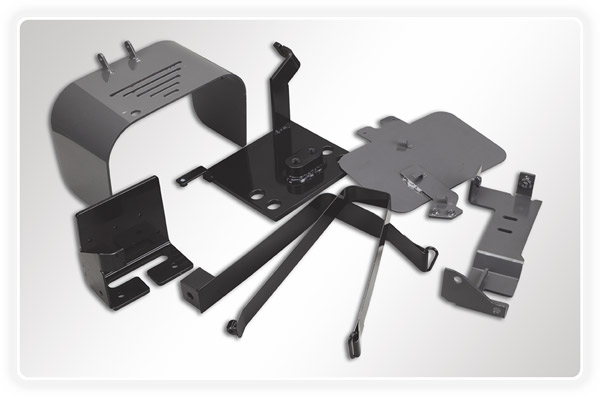

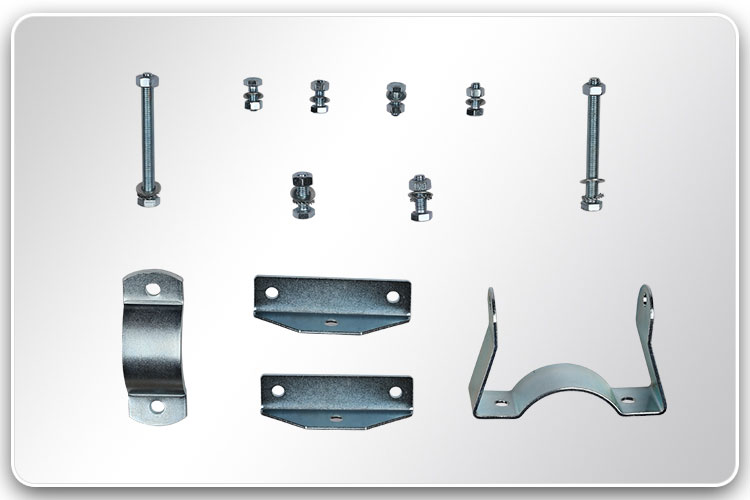

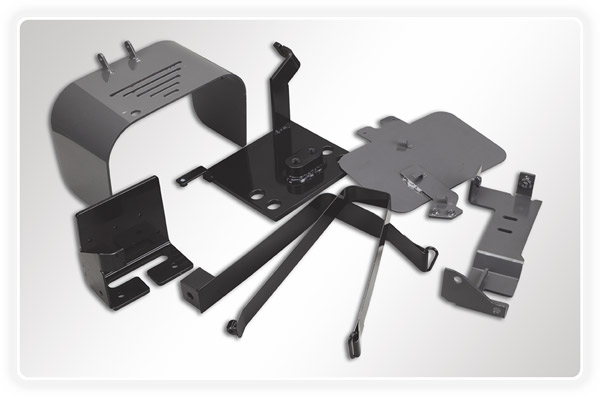

Auto OEM Parts

Auto OEM Parts

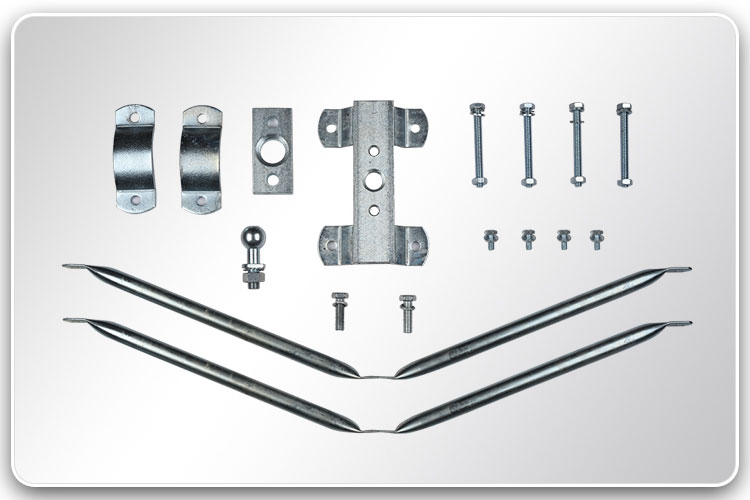

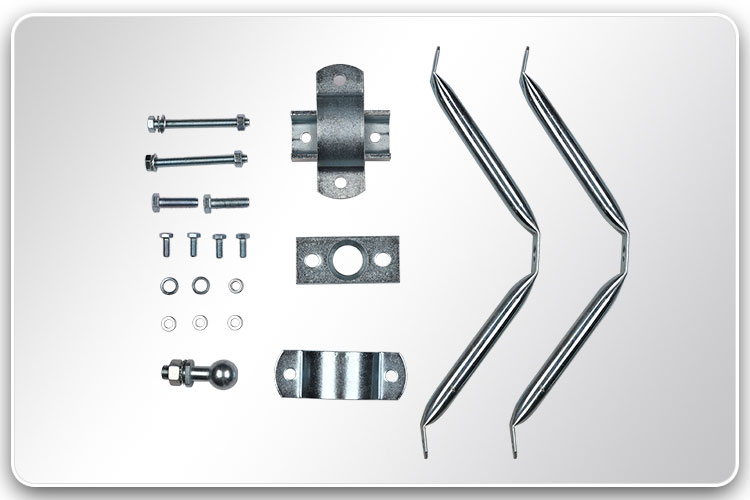

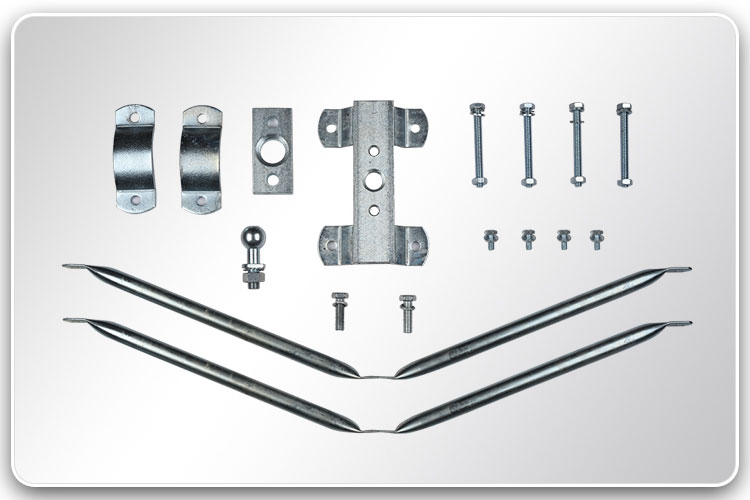

Music Adjustable Torsion Bar

Music Adjustable Torsion Bar

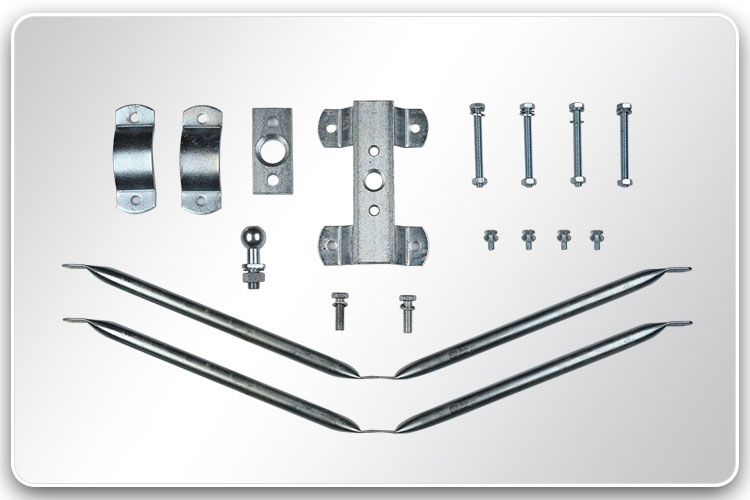

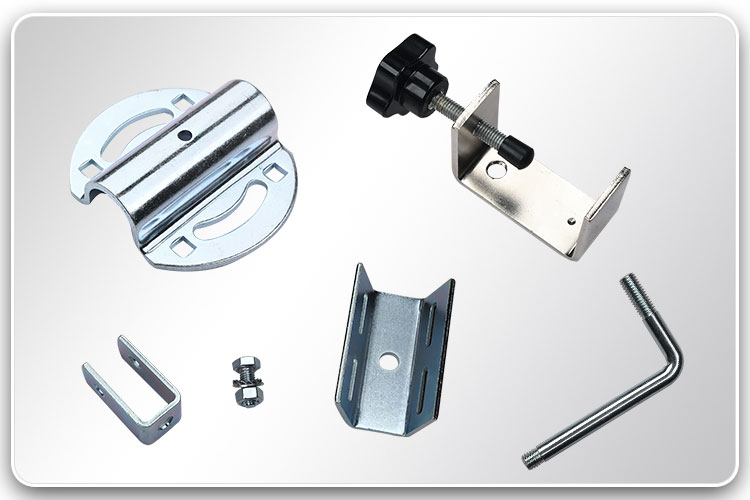

Re Rustica OEM Parts

Re Rustica OEM Parts

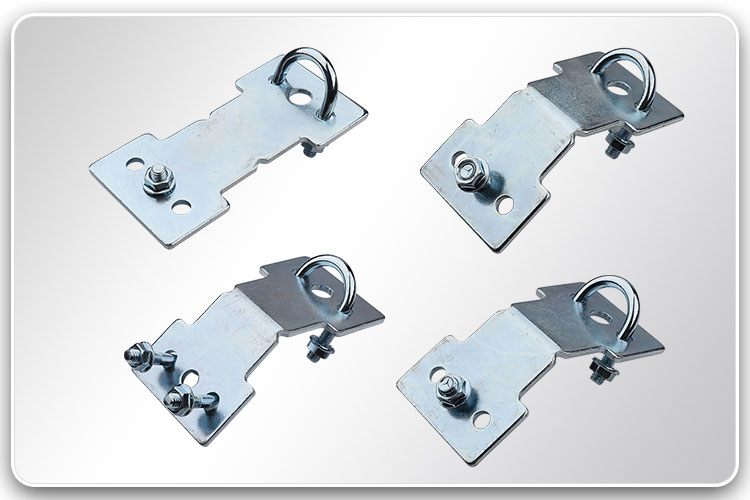

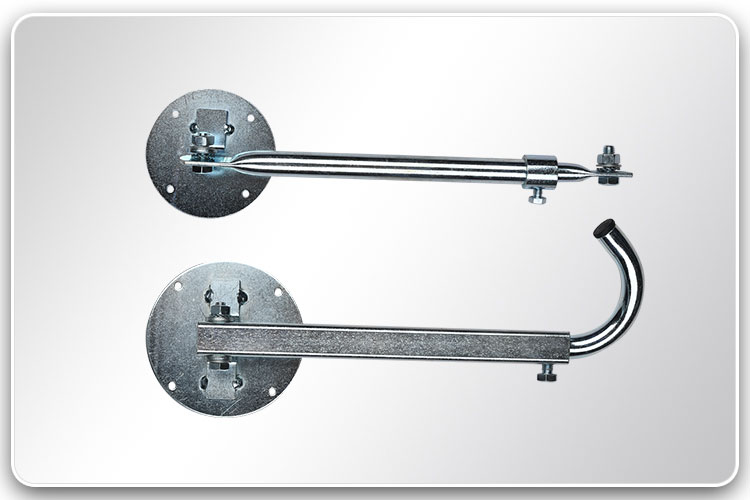

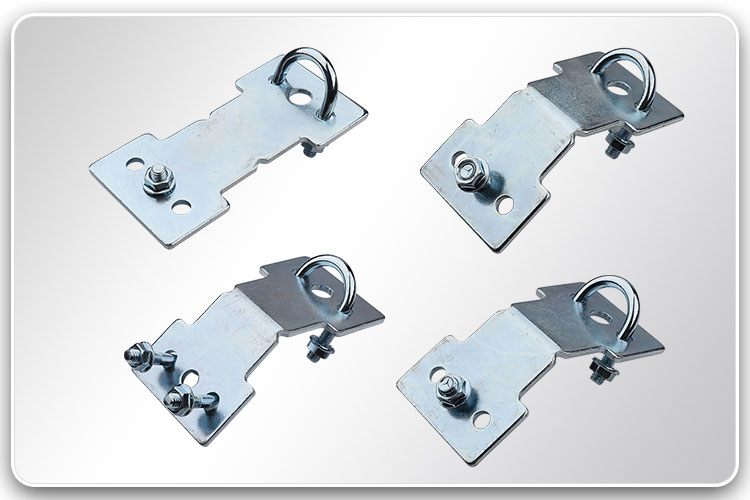

Mirror Bracket

Mirror Bracket

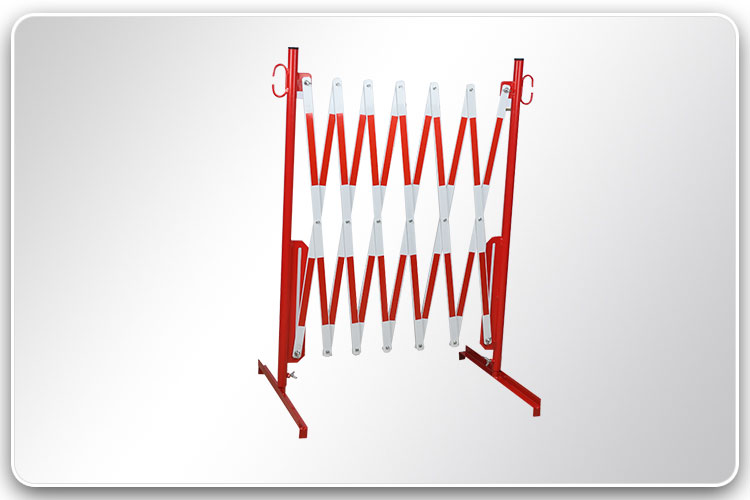

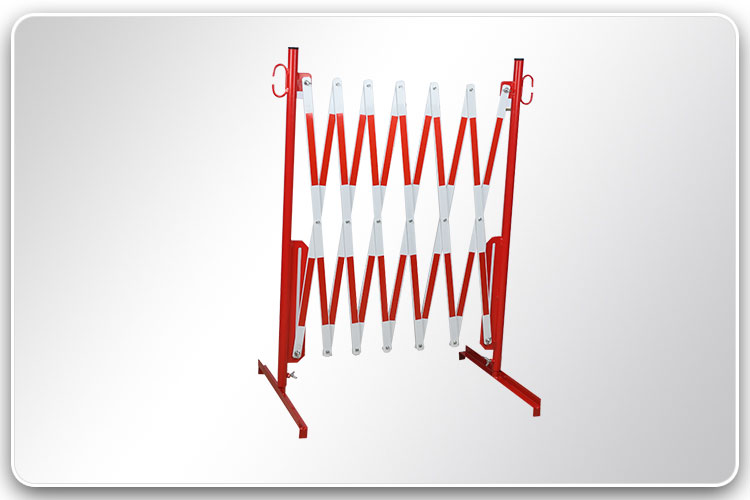

Obice emittendo Sets

Obice emittendo Sets

Crash Protection Guards;

Crash Protection Guards;

Bracket tetigisset domatum fistulas et Folium editions Filter

Bracket tetigisset domatum fistulas et Folium editions Filter

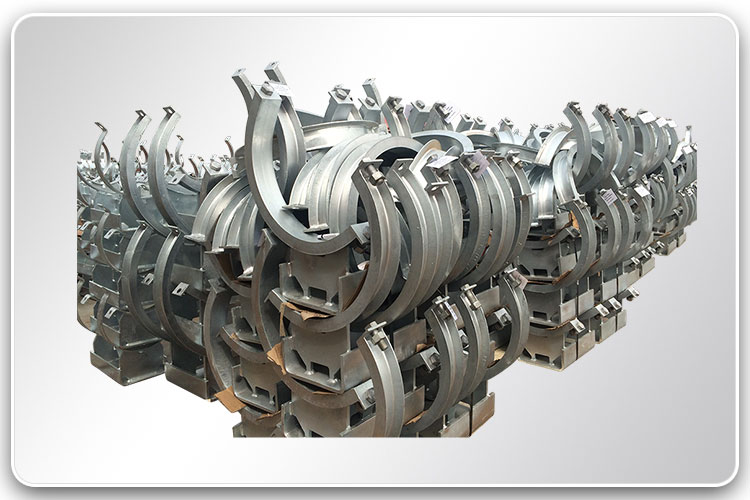

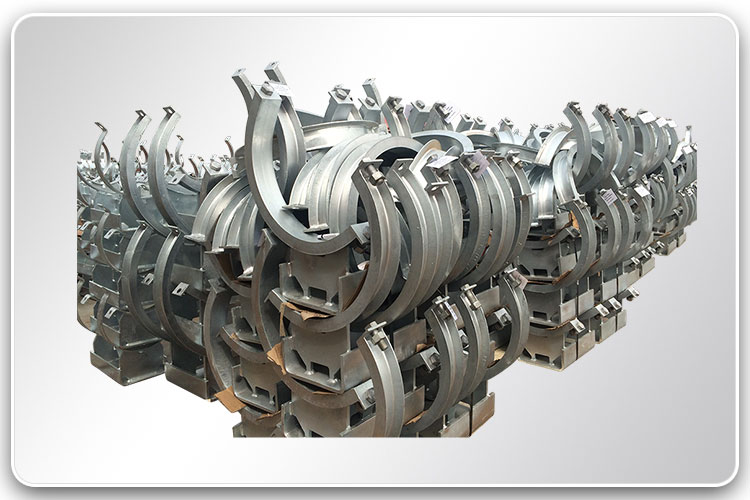

Mauris pellentesque pipe

Mauris pellentesque pipe

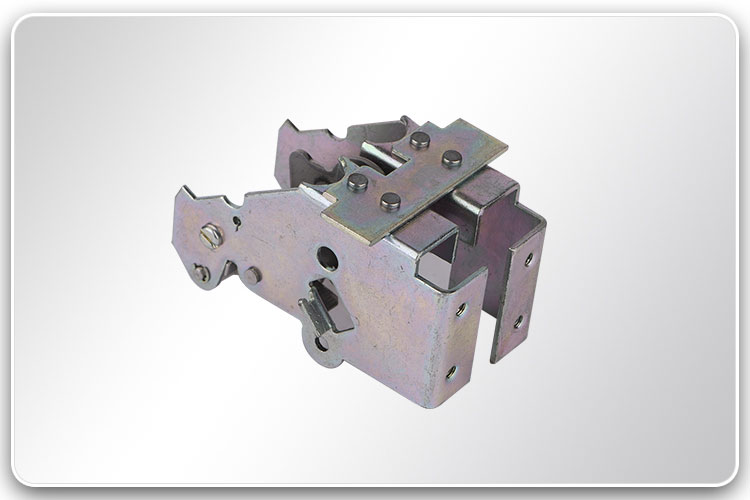

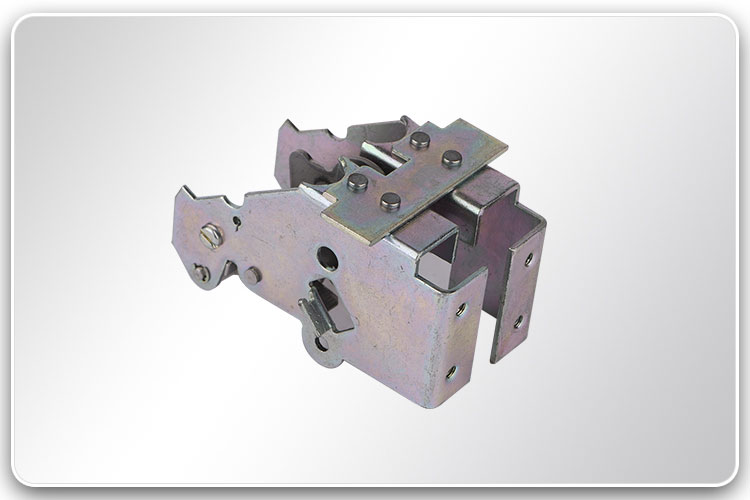

Power Cabinet Switch

Power Cabinet Switch

Festinaverunt itaque Racking Partibus

Festinaverunt itaque Racking Partibus

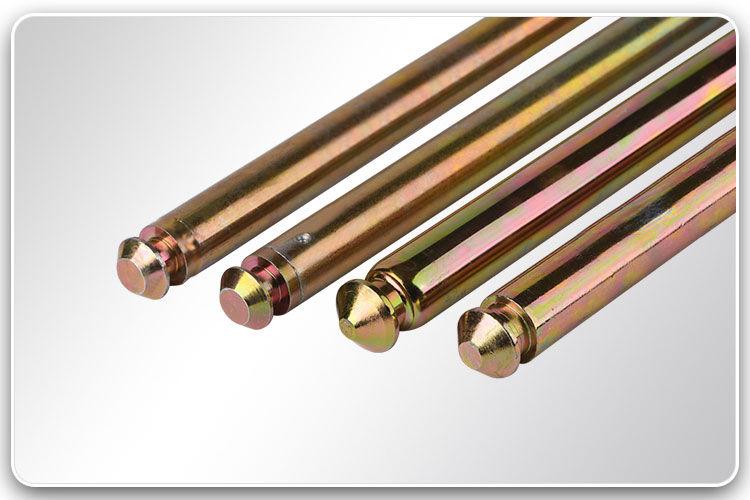

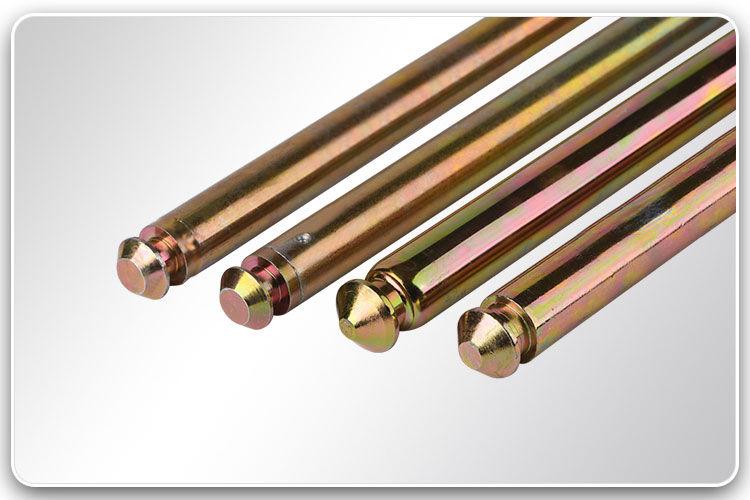

Wheelie Bin Axle

Wheelie Bin Axle

partes supellectilem

partes supellectilem

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик