Description

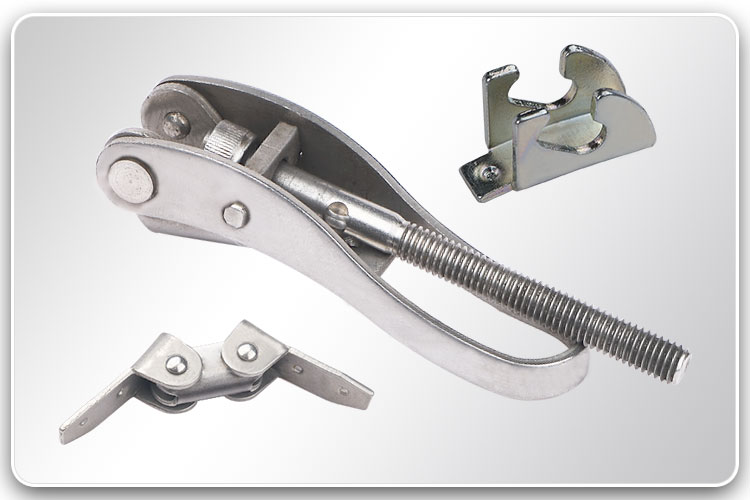

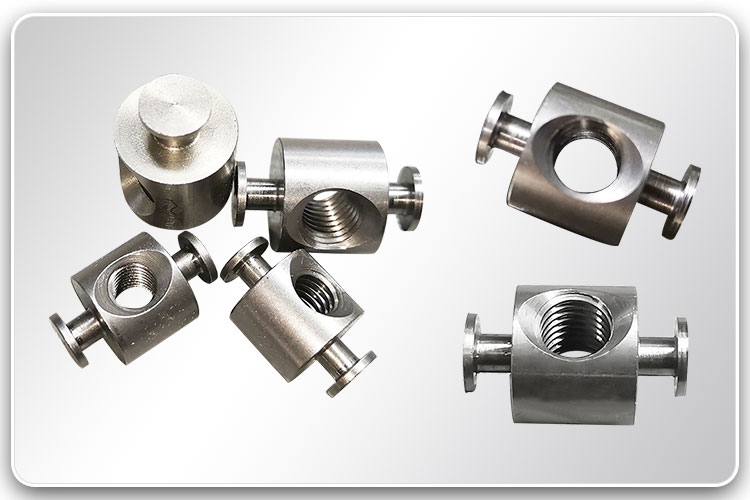

Tune enim clamping annulos partes sunt essentialia components ad circulum clamping products. Quod si anulum est de occlusione ex parte longiora retro manipulis et linteaminibus, et seras, unus paro consistit ex clamping annulum conversus, fere IV partes. Et Î|12mm Î|14mm sunt maxime vulgaris diametrum. II De ordine consistit clamping inaures anulos clamping conversionem singulos enim Î|12mm diametro foramen unum sectio M6 6.5mm aliud foramen filum quoque foramina fila Î|8.5mm domibus M8 conversio Î|14mm partes enim clamping annulos.

Conversus autem partes de chalybe annulos clamping superficiem plated cadmiae, cadmiae per default album esse plating. Idem facile aversio filo partibus foramina obducta cadmiae Plating flavis.

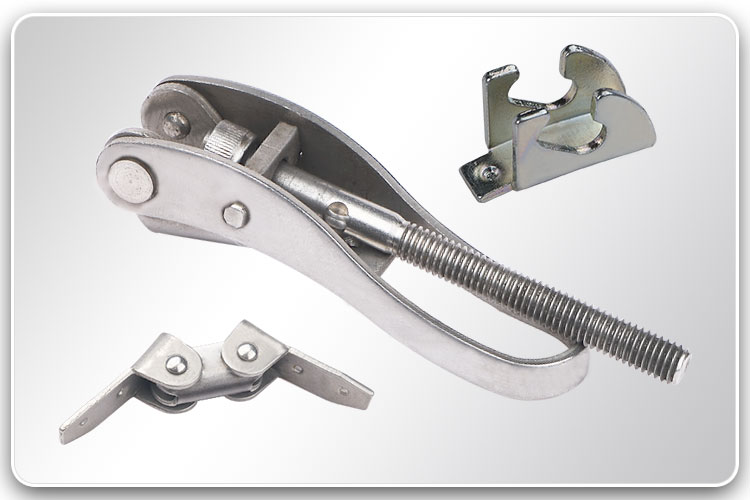

Sed in eo discrimen verti per puncta diametri includit partium ad clamping annulos control brachium tolerantia de area, et qualis est foraminis tranquillitatis vestigium; lappa et circa area percussoque sequela foraminis. Etiamsi simplex adventum sine machinis et rectam processus, qualis quaestiones possint de facili relevantur.

Cum XV annorum conversus professio ex partibus enim clamping annulos productio experientia, Auwell has developed id maxime esse efficiendum via producendo huic conversioni repugnaret partes.

In hoc video in vestibulum processus monstrat convertendi se ad partes clamping annulos:

Currently, 100% of our turning parts for clamping rings are exported to Germany for our distinguished clients. By using optimized technology and programming, our products are proven to have excellent quality while having an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

The Turning Parts for Clamping Rings displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Technical Specifications

-Material: ST12, ST37, Q235B, Stainless steel 304, 316L or upon request

-Conversus partes diametri: M6 Î|12mm cum filo ad orÎ|14mm filo postulante M6

-Superficiem treatment: plating Stannum autem vel immaculatam ferro, quia et ipsum

-Sarcina: plastic peram: et currus capsa lignea.

commoda,

-Usus rich

More than 15 years of experience in this particular turning parts for clamping rings development and production, especially to the European markets. With solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

Plerumque, providere nobis est in quotation II working days. Coniunctis tardus technologies et vestibulum facilities, Auwell potest providere samples in annulos clamping ad partes conversus iustus a septimana.

-Solutio in comprehensive Providentem

Auwell praebet comprehendo muneris convertendi se ad partes clamping annulos projects incipiens a navigare cogitans, et per prototyping, sampling, massa productio et logistics et post-venditionis firmamentum.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Payment termino flexibilia

Nam massa productio, si termini solucionis offer flexibilior, rationabile verbis fidei et daretur, nisi componat ad client cum sunt beati per productum accepit. Diu terminus consiliorum vocem laudis fuistis inventarium ieiunium partus officia requiruntur.

Related Products

Saddle for Clamping Rings

Saddle for Clamping Rings

Fast Connector for Clamping Rings

Fast Connector for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик