Certe ut rota rotae centrum assemblyincludes uertor clauorum vehicleto suspensionis et currus et ascendens gubernaculo Frontend ratio in finem et extremum agmen axes.

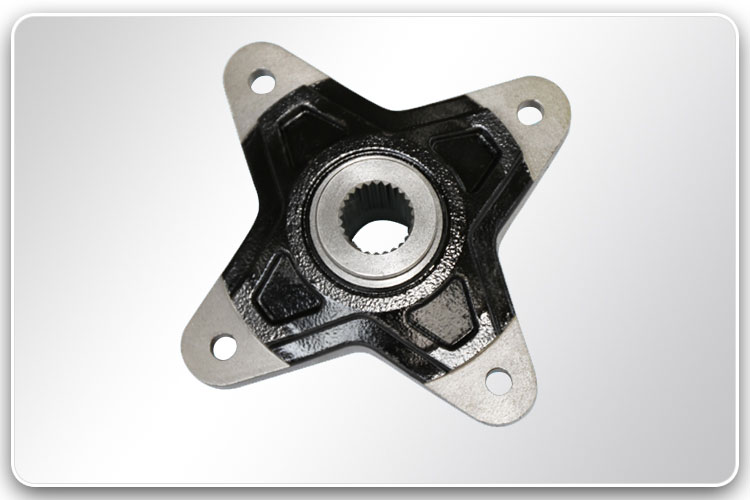

Auwell wheel hub

is mostly made by forging followed by CNC milling, then surface treatment. In

some cases, investment casting is also the process for production. The material for wheel hub mostly is alloy

steel but some of them made by aluminum. As an OEM components supplier, Auwell

develops wheel hub in accordance with clients’ drawings and specifications.

Auwell’s contract manufacture is specialized

in producing different kind of wheel hub and steering knuckles, spline

connectors as well as spline sleeve parts for automotive industry.

Proponendum imaginis isfor productio ostendit facultatem nostram. Wheelhub clients qui sunt interested in productum progressionem, misericordiam nobis placere contactus details.

commoda Auwell

-Rich Experience

More than 10 years of

experience in Wheel Hub products development and production, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Plerumque, ut opus providere a quotationwithin III diebus. Coniunctis fabrica tardus technologies andfacilities, providebit ieiunium Auwell potest prototypes in II weeks iustus pro simpleprojects.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Wheel Hub projects starting from designing, through

prototyping, tooling/fixture development, sampling, mass production, and to logistic

and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. For quality control of Wheel hub parts, we provide set

of test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with TS16949 requirements and drawing

specifications.

-Payment termino flexibilia

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Nam singula AboutOur steering percussit, et connexiones spline Spline Women partium misericordiam pleasevisit his links:

steering Knuckles

Spline Connector

Spline Sleeve Parts

Quia partes sunt sequentes catalogi centrum rota Auwell hasproduced suppleverunt amplissimi orbem elit. Please click for details imaginibus therelevant. Quaeso consilium, maxime in products sunt fordemonstration proposita tantum.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик