Auwell started Wheelie Bin Axle products for European and North American market 10 year ago. The most common wheelie bin axles are for 80 litters, 120 litter and 240 litters bins. However, we offer all different kind of axles based on clients’ drawing specifications.

Fere hoc frequentissimum moles nostris demovere;

-Ф21.5mm (0.85”) * 522mm (20.55”)

-Ф19.0mm (0.75”) * 576mm (22.67”) White bin

-Ф19.0mm (0.75â) 597mm * (23.50â) viridis bin

-Ф19.0mm (0.75”) * 646mm (25,43”) Orange bin

And many other items.

Sunt genera Wheelie bin axe IV

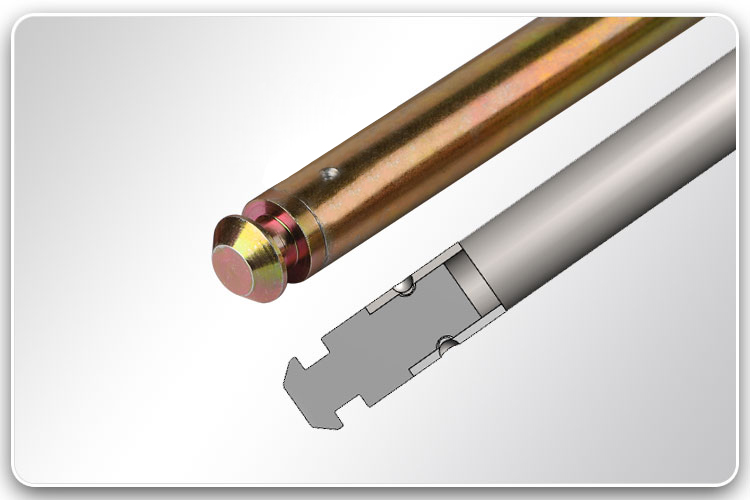

-Wheelie Bin Axle Solid

This axle is directly milled from steel bar, the bar is fine drawn to desired diameter, them 2 side milled to required dimensions followed by surface treatment. This is normally used of heavy-duty wheelie bins. Surface treatment normally is zinc plating.

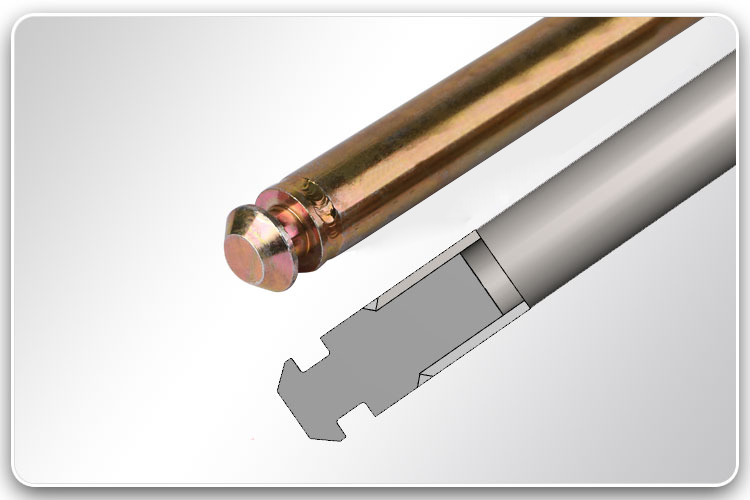

-Wheelie Bin solidum sed inane Axem

Haec recta axem positus est, ex ferro fistulam. Desiderabilia prae ducatur diameter tubi ferrum sequeretur in formando aliqua. Nos have processus developed per specialem machinis atque formatam. Crassitudines quam tubo 2mm impares cunctarum Wheelie rectae. Aliasque eiusmodi axis sit finis status, est etiam finis aperire inceptos. Iactaret superficiem et cadmiae-plating rubigo in praesidio.

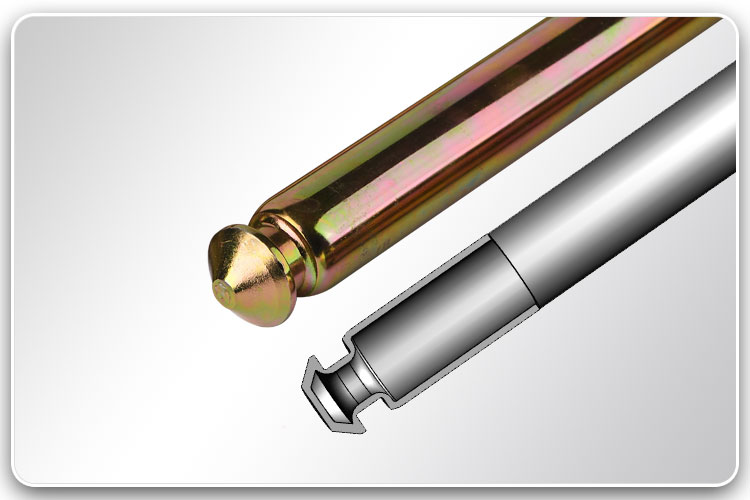

-Wheelie Bin solidum sed inane Axem with Solid Head Welded

Hoc factum est ab axe corporis et ferro fistulam est, serratos bigatosque ex ferro bar Caput II parte. Capite axis corporis convenerunt Vicifontem. Utilitatem hoc genus est, axem, axis has vires similis apud unum completum solidum sed vilior esse levius pondus et pretium. Superficiem treatment peragatur in ultima post Vicifontem.

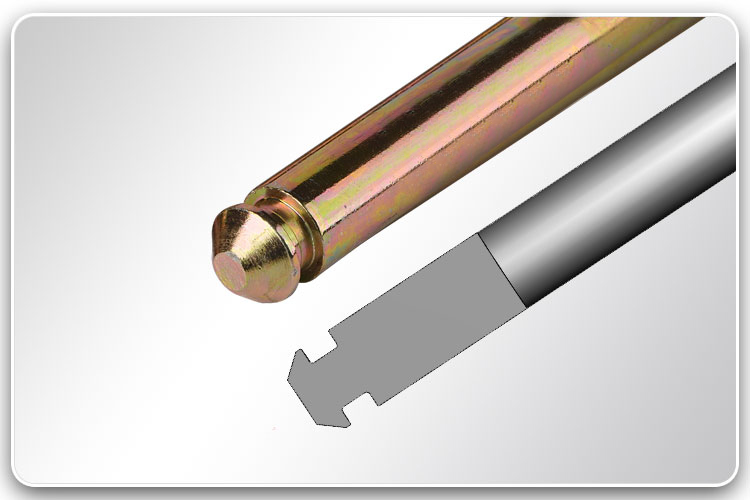

-Wheelie Bin solidum sed inane Axem with Solid Head Stamping Assembled

Hoc factum est ab axe corporis et ferro fistulam est, serratos bigatosque ex ferro bar Caput II parte. Congregatis principibus puncto axis terunt in oppositum corpus capiti membra tractus cum moliti praeexistunt, sicut punctum datum in rimam strepitu hanc collectionem fac stabile est. Utilitatem hoc genus est, axem, axis has vires similis apud unum completum solidum sed vilior esse levius pondus et pretium.

Auwell has rich experience in Wheelie Bin Axle manufacturing. We are in extremely strong position in Wheelie Bin Axle production capability and, our competitive price and favorable payment term have received great praises from our clients.

Technical Specifications

-material

Mitis ferro bar, ferro fistulam

-Other specifications

Et per huiusmodi intelligibiles designing necessaria developing pro tools comprehendo Wheelie Bin Axem products formatam perit, fixtures pro welding est, et massa productio test gauges ad QC. Superficiem treatment includit KTL et pulvere coating, et zincum pingis plating. Chat fluxus Control Plan et erit subiciantur ad disputationem volueris clientem cursus ante productionem.

commoda,

-Rich Experience

More than 10 years of experience in Wheelie Bin Axle products development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

Fere, ut in III opus providere a quotation diebus. Coniunctis tardus technologies et vestibulum facilities, providebit ieiunium Auwell potest prototypes in II weeks iustus.

-Comprehensive Solution Provider

Auwell provides comprehensive services for Wheelie Bin Axle products starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Payment termino flexibilia

Auwell offer flexible payment terms, reasonable credit terms will be given, client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик