Description

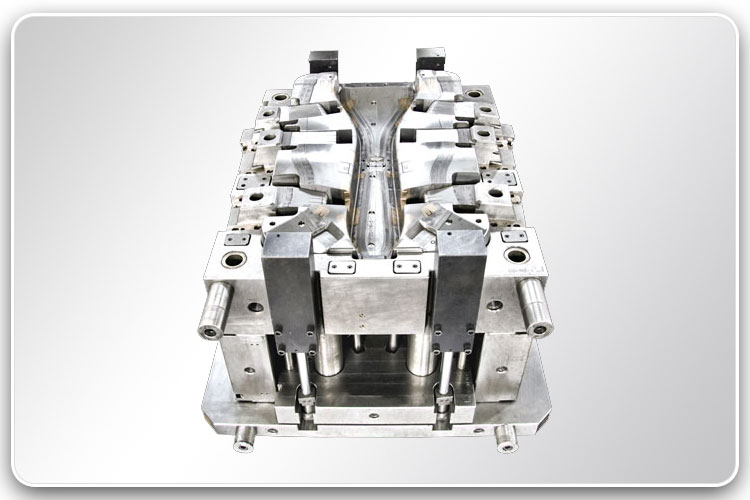

Injection molding is a vestibulumprocessus in producendo conflatilem materia in partes per injectingfingunt. Plastic Injection Molding is one of the most frequently used vestibulum

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

The plastic injection molding process requires an injection molding

machine, raw plastic material, and a machined mold. The raw plastic material is

first melted in the injection unit and is then injected into the mold, where it

cools and solidifies into the final plastic part.

A key gradus iniectio auro processus in includit:

-Clamping

The two sides

of the mold are closed and clamped shut.

-Injection

The material is fed into

the machine and pushed towards the mold. While this is happening, the material

is melted by heat and pressure. The plastic is then injected into the mold,

this process is called “Shot”.

-Refrigerant

Forma in formam et consolidat refrigerare plastica partem attrahunt.

-moribus deductio

Post partcools est eiectus fingunt.

Auwell II negotium offert exempla monstrabit, ut responderi valeat exigentiis de projects Clientem forplastic iniectio auro. Donec nisi est copia tooling vel finalproducts Donec.

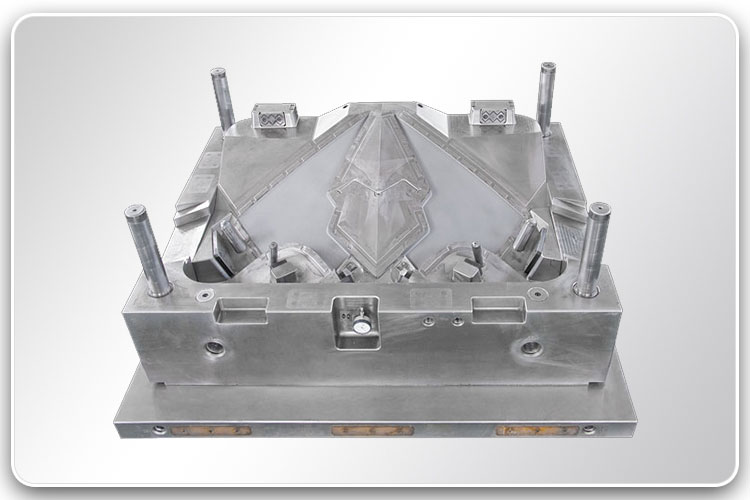

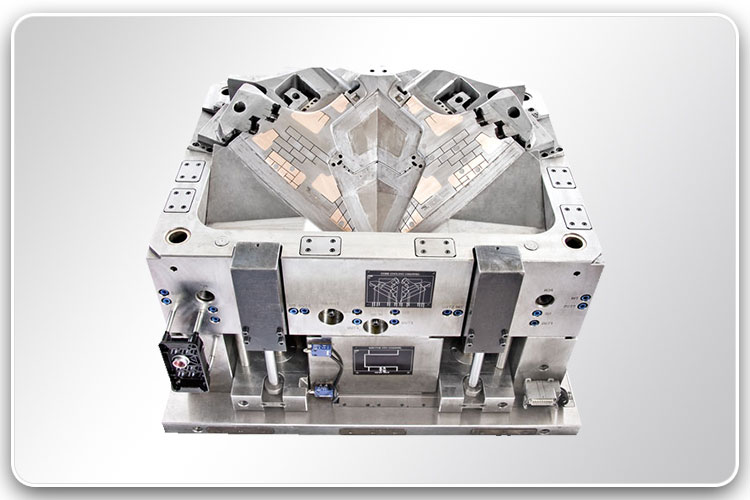

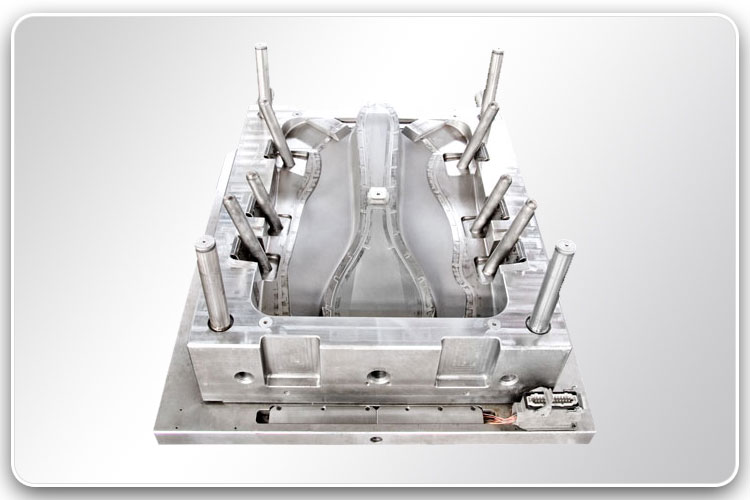

-Tantum in exemplum Tooling

For this business model,

Auwell offers the tooling design based on the product design and machine data

for client confirmation, the details include tooling structure, lifetime,

tooling material, hardness, etc. Clients may provide completed tooling designs

for production. For this tooling only option, for standard parts, we will use the

most common with globally recognized one for easy maintenance. In general, this

option is preferred for large size and high-volume products, Plastic

Injection Tooling Automotive is a typical catalogue for this business

model.

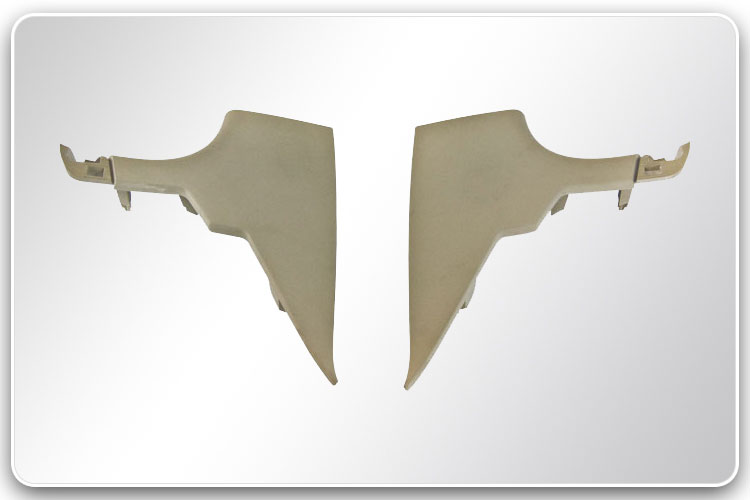

-In exemplum ultima Products

For this business model, Auwell is responsible for the plastic injection molding parts, and to meet the client’s specifications. The type of injection machine and tooling structure/design used is decided by our team. For this business model, once the client pays the tooling cost, Auwell will be responsible for tooling maintenance and replacement for the entire product lifetime. This model is preferred for small sizes and precise plastic injection molding parts. Please refer to “Iniectio plastic partes” section for more details.

Alius key distinctus in duos negotium exemplar est in Tooling OnlyModelâ, quod est multo altior quam sumptus fingunt Si Vis Pacem Products Products Modela final Modela et fora clivus erat, non facit aliquam Auwell a margine toolingdevelopment. Si Vis Pacem, Modela Products Nam si vis accipere moldor clients, subcinctus alii elit, non est praestati ut fingunt worksproperly modo machina modo faciendi, et quaedam proportionof progressionem fingunt pretium sit amet ante transferendis in fingunt.

Apart from plastic injection molding, we also provide the following

services:

-Rapid 3D printed prototypes

-Overmolding

-Insert molding

-Thermoforming

-Flexilis & SiliconeMolding

Technical Specifications

-Material

Following plastic

material available for our plastic injection molding services:

Ø PA 6/6 | Polyamide 6/6, Nylon 6/6

Ø PARA | Polyaryl Amide

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT, DELICIAE | Polybutylene Terephthalate Polyethylene Terephthalate,

Ø PC | Polycarbonate

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø DELICIAE PC-| Polycarbonate, Polyethylene Terephthalate

Ø Princ | Polycyclohexylenedimethylene Terephthalate

Ø FE | polyethylene

Ø PE-PP | Polyethylene-Polypropylene

Ø PE-PS | Polyethylene-Polystyrene

Ø PEBA | Polyether Block Amide

Ø PEEK | Aether Polyether Ketone

Ø PEI | Polyetherimide, Vivamus neque

Ø PES | Polyether Sulfone

Ø PET | Polyethylene Terephthalate, Rynite

Ø PLA | Acidum Polylactic

Ø PMMA | Polymethyl Methacrylate, Acrylic

Ø POM | Acetal Polyoxymethylene, Delrin

Ø P | Polypropylene

Ø PPA | Polyphthalamide

Ø PPS | Polyphenylene Sulfide, Ryton

Ø PS | polystyrene

Ø PS-PPE | Polystyrene, Polyphenyl atmosphaeris aethereis, Vivamus neque

Ø USU | Polysulfone, Udel

Ø PVC | Polyvinyl Chloride (Shore D)

Ø PVDF | Polyvinylidene Fluoride

Ø San | styrene Acrylonitrile

Ø TPO | Thermoplastic Polyolefin

Ø TPU | Thermoplastic Polyurethane (Shore D)

Ø Custom-radix resina

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Active Elements

Ø P20, 1,2311, 1,2312, 1,2738, 1,2343, 1,2344, H11, H13, CDXX

Ø ASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5: S-stella (A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Mould Surface

Photo Criofractura, erodestructure ducens Blaster linea expolitio magna crassa expolitio, mirrorPolishing.

-Machinis, 100-3,000 vis tonclosing

commoda,

-Usus rich

Magis quam XX annis in plastic iniectio auro ofexperience tooling parte productionem et progressionem, praesertim in North American et Europae fora, cum solidum understandingof in materia, et qualis technica signa terrarum.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest vestibulum

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-Solutio in comprehensive Providentem

Plastic iniectio auro Auwell providescomprehensive servicia pro projects fromdesigning incipiens, per prototyping, tooling / fixture progressionem, sampling, massproduction et logistics et post-venditionis firmamentum.

-Seu Rigidorum VOL Politiae ipsa QC;

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

For tooling, the general

payment term is 50%-40%-10%, meant 50% deposit, 40% after first sample free and

10% 2 weeks after client receive tooling or first batch product delivery. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Applications

-Plastic iniectio moldingproducts et late iam in omnes fere odio sectorsincluding:

-Aerospace et tutamen

-Automotive

-Latina Apparatus

-Energy

-Electronics

-Construction

-Transportation

-Industrial

-Consumer Products

De his autem catalogs plastic iniectio auro productsare ones, qui est productum Auwell suppleverunt distinguishedworldwide nostra clients. Please click in imaginibus pertinet ad singula. Placere beadvised, maxime in products sunt enim modo ad demonstrationem.

Iniectio plastic Molde pro Automotive Parts

Iniectio plastic Molde pro Automotive Parts

Iniectio plastic partes

Iniectio plastic partes

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic partes Thermoforming

Plastic partes Thermoforming

Rubber & Silicone Molding

Rubber & Silicone Molding

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик