Description

Cnc (computatrum imperium numeralis) machining est milling thatemploys computerized controls processum, circumducitur vel amputatis testiculis Multipoint instrumenta toprogressively removere a materia in workpiece, producendo designedparts quod consuetudo-products. Cnc machining producendos sit idonea, princeps accurate, hightolerance prototyping partes ad unum-off, productio et parva et medium fugit.

Machining mechanicae via est cnc machining cum artem conversus et aliis diversis processibus Machining. Cnc machining ad a 2D vel 3D Nulla processbegins cum creatio (Computer-adiutus Design) partim consilio. Quod est exportata ad perficitur consilio CNC-compatible per andconverted formae q.e. CAM (Computer-adiutus Manufacturing) software. Quod progressio quod lima isimported in cnc apparatus locutus est actus est motus de machineand tooling per workpiece.

Once the milling operation is completed, the milled parts proceed to the

finishing and post-processing stages of production which include grinding,

deburring, heat treatment, surface treatment, etc.

There are several types of CNC machines — namely the CNC lathe, CNC mill, and Wire EDM.

Cum enim CNC torno, in stirpe ad partes turn ad fortia, et adduxistis in contactum cum sit instrumentum fixedcutting workpiece. Lesti partibus perfectum facile forcylindrical repeatability summa constituatur. Vice versa, ona cnc molendinum circa movet motu turbinatorio a tool ad scindendum in workpiece, qui remainsfixed ad lectum. Maxime autem omnium causa tractatur molendina cnc anymachining apparatus processus.

Cnc machinis potest esse simplex II-axis apparatus ubi caput instrumentum movet in onlyin X & Z, axis, vel axi cnc quanto magis universa V, frangebat mola, ubi movere et workpiececan. Et hoc concedit pro quaesitiore structurae ac rerum agendarum peritia opus operator extra withoutrequiring et formas adfero. Hoc facit ut facilius partes producecomplex et reduces operator est forte in errore.

Antiquus Morte filum electrica defluxiones (EDMS) tollit totaliter esse diversas approachto cnc machining, sed confidunt in PROLIXUS materiae electricae atque erodethe ad workpiece. Hoc processus in futurum succides aliquo PROLIXUS materia, inter allmetals.

Auwell is capable in CAM programming for high efficiency and desirable

quality. The Auwell team can design the necessary fixtures and tools for the

milling process and test gauge for mass production quality control. CMM is

available for sample dimensional inspection. Surface treatments include

grinding, polishing, electrochemical deburring, KTL, powder coating, painting,

zinc plating, nickel plating, chromating, blackening and laser marking, etc.,

for aluminum parts, anodizing and silver plating is also available. PPAP

documents are available upon request.

Cubits technical

CNC machining technology allows the process to machine parts of a wide

range of materials, including:

-Metals (including alloys,

exotic metals, heavy-duty, etc.)

-Plastics (including

thermosets and thermoplastics)

-Elastomers

-LATERAMEN

-compositis elatis

-speculo

Auwell focuses on the following metals for CNC machining: mild steel,

stainless steel, copper, brass, aluminum, and alloy steel. With the

pretreatment of extrusion, hot forging, cold forming, investment casting,

die-casting, etc.

Machina facultatem: Conversio princeps torno cnc torno rasile II-V-axis et axis CNCmachining machinis et aliis machinis inter pertinet stridor machinis demittantur, machinis, filum Conscidisti machinis. Nos can utor apparatus forproduction maxime idoneam ad ad desideravit qualis esse in cost-effective.

Advantages

-Rich Experience

Magis quam XX annis ofexperience in productionem et progressionem products cnc machining, praesertim tothe North American et Europae fora, cum solidum thematerial intellectus, et qualis technica signa terrarum.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 2 weeks

for simple projects.

-comprehensive SolutionProvider

Auwell cnc machining ad officia providescomprehensive incipiens a navigare cogitans, et per prototyping, tooling / fixture progressionem, sampling, massa productio et logisticae andpost-venditionis firmamentum.

-Rigid QC Policies

The most rigorous quality

policy starts from material control and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. Other reports include dimensional reports,

surface treatment thickness, and salt fog test reports, etc. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Payment termino flexibilia

Nam massa productio, weoffer termini solucionis flexibile, rationabile ut fidem verbis data, componat ad clientonly uber quod hi beati sunt; apud eos suscepit. Diu termprojects offerimus ieiunium partus officia vocationis inventarium procul elit.

Applications

CNC machining products have widely been used in almost all industrial

sectors including:

aerospace and defense, automotive, energy, industrial machinery, medical,

robotics, and R&D.

-Aerospace et tutamen

-Music

-Robotics

-Energy

-Electronics

-Medical

-Transportation

-Industrial machinery

-Consumer Products

De his autem catalogs cnc machining products arethe ones, qui est productum Auwell suppleverunt worldwideclients insignes nostrae. Please click in imaginibus pertinet ad singula. Quaeso consilium, et products sunt maxime per demonstrationem proposita tantum.

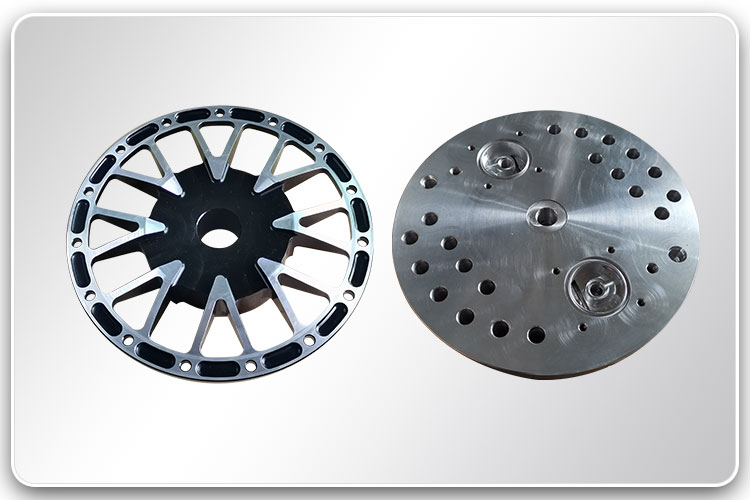

Car Partibus Modification

Car Partibus Modification

CNC Machining Assembling

CNC Machining Assembling

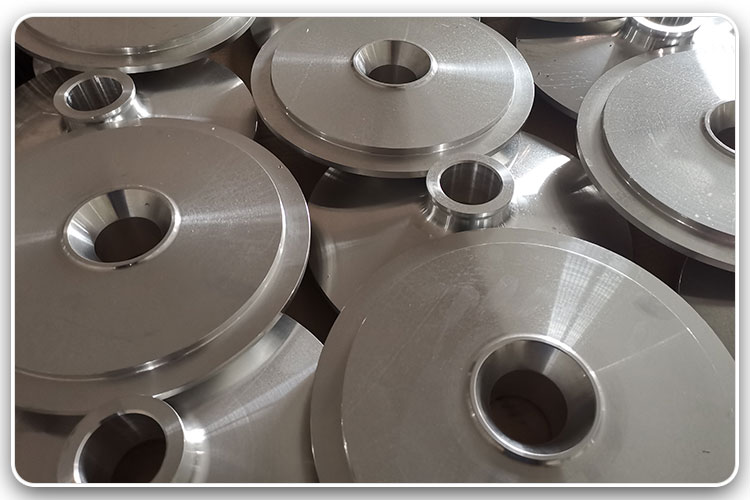

CNC Machining cylindro Partibus

CNC Machining cylindro Partibus

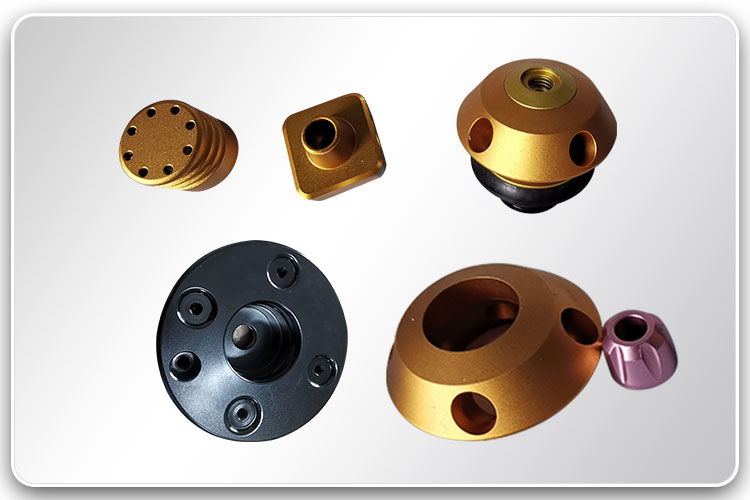

Custom Made Fastener

Custom Made Fastener

CNC Machining Parts

CNC Machining Parts

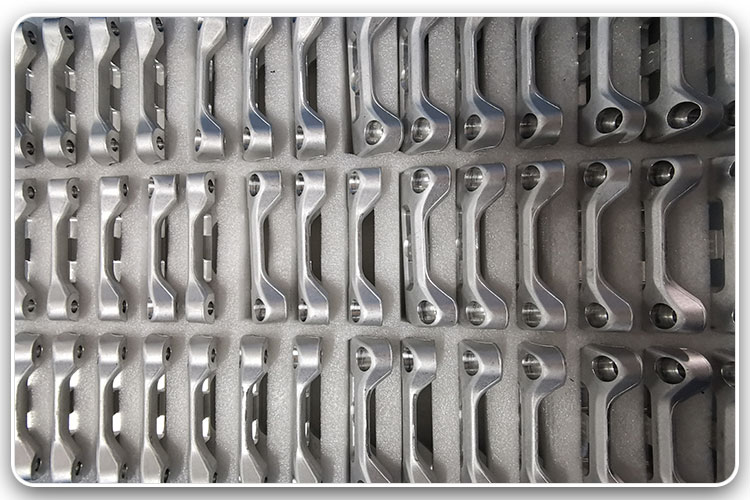

Spline Sleeve Parts

Spline Sleeve Parts

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик