Description

Die casting is a metal casting process that is characterized by forcing

molten metal under high pressure into a mold cavity. The mold cavity is created

using two hardened tool steel dies and work similarly to an injection mold

during the process. The typical material for high pressure die casting are

aluminum, zinc, magnesium, copper, and tin-based alloys. Depending on the type

of metal being cast, a hot, or cold-chamber machine is used. Auwell typically

provides services for hot chamber aluminum and zinc die casting molds and

products.

Fusura una die altissimo premit fieri vel plures sinus usum

De unit moriatur aut compositum ex perit quod productum necessario pendent.

Different type of dies in the die casting process:

-Single cavity to produce one component

-Idem pluribus locis plures sinus esse

-Unit die to produce different parts at one time

-Aliquot simul partibus ad ecclesiam die

Magno apparatu et dejectio illorum in caput costs referunt metallum perit. Ita maxime apta parva magnam itis sizedcastings medium, quare moriuntur altissimo premit telorum iactu plus ceteris Castings thanany elit. Princeps pressura mori casting plane distinguitur vera excellentsurface consummavi quod (per signa casting) et dimensional cura.

Nunc considerandum est, cum princeps pressura mori casting cīvitās industrialis est ratio partium usus ad fabricabimus pro sale, vel ut ulla pars in machinis aut othercommercial industriae productio. Et concedit productio processus est a accurateproducts desideravit Amplitudo cornuum et figura et crassitudine sunt stricta tolerances, faciens eam maxime simplex processus casting sed effective, quia essential creatingmetal singula certa sunt partes et species requirit.

Proven fructus operis est et mori princeps pressura casting products. In thisprocess, et alii possunt facta est productio. In pecunia minus minusque Manufacturersspend producta fuerit faciendum, misit partswhich venustiores oculis emptores.

High pressure die casting can eliminate post-machining and repeated

molding. The process is very economical and finished products made under this

process are accurate and long-lasting.

Princeps pressura est mori casting agentibus, oeconomicos processus abroader obtulit range ex formis geometricis et alia components est faciens tamdiu a technique.Parts vitam et ministerium ad complent in ea materiam esse visualappeal parte in circuitu.

Advantages of high-pressure die casting are as following:

-High-Speed Production

Summus pressura castingsupports mori in universa shapes propius tolerances comparari massproduction multis aliis processibus. Machining parum aut nihil sit, requiritur quod sit produci possunt priusquam castings ofidentical millibus additional tooling non requiritur.

-Excellent dimensional accuracy and stability

High pressure die casting

produces parts that are durable with dimensional consistancy while maintaining

close tolerances. They are also heat resistant.

-Vires pondusque

High-pressure die casting

parts have considerable high tensile strength at 415mpa. Thin wall castings are

stronger and lighter than those possible with other casting

methods.

-Multiple finishing techniques

Summus pressura ad lenis produci non posse mori castparts-textured superficiem, et quae easilyplated cum consummatum vel minimum superficiem praeparatio.

-simplicior ecclesiam

High pressure die casting

provides integral fastening elements, such as bosses and studs. Holes can be

cored and made to size using tap drills, external threads can otherwise be

cast.

Auwell offert servicia et compleretur clientsâ formas consociatas in campo elit. Habemus dives usus est in ordinatione et vestibulum highpressure worldwide mori casting instrumenta ad forum, praesertim EU terris. Weproduce perit et proiici eos amet, et inter machining Superficiem treatment: forour clients.

Cubits technical

-Core elementum Material

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Caput Material: P20,1.2312, 1,2738

-Standard Components

HASCO, LKM ducuntur vexillum seu custommade

-Popular Product Material

AL226, AL230, AlSi10Mg,

360,380,383, 413 and A304 K-alloy, ADC12, ADC10, Zamak 3, Zamak 5, ZA-8, ZA-12

and ZA-27 etc.

-Superficies uber in consummatione

Includes but is not

limited to: brush, line polishing, high gross polishing, mirror polishing, sand

blaster, anodizing, zinc-plating, chrome-plating, nickel-plating, powder

coating, silver coating, E-coat, wet paint, silk screening and stenciling etc.

-Maximum Machining Closing

Force

4,000 tons, part weight:

5-30,000g

Advantages

-Usus rich

Magis quam XX annis ofexperience productionem et progressionem products casting mori in altum pressura, especiallyto North American et Europae fora, cum solidum thematerial intellectus, et qualis technica signa terrarum.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide initial samples in just 5 weeks

for simple projects.

-Solutio in comprehensive Providentem

Mori incipiens fromdesigning projects casting Auwell providescomprehensive officia pressura est princeps, per prototyping, tooling / fixture progressionem, sampling, massproduction et logistics et post-venditionis firmamentum.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. Other reports include dimensional reports,

surface treatment thickness, and salt fog test reports, etc. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Flexible Payment Term

Nam massa productio, weoffer termini solucionis flexibile, rationabile ut fidem verbis data, componat ad clientonly uber quod hi beati sunt; apud eos suscepit. Diu termprojects offerimus ieiunium partus officia vocationis inventarium procul elit.

Applications

Princeps pressura mori late fusis products sunt fere sunt usus apud comprehendo allindustrial aer discrimina accipit:

-Aerospace and defense

-Music

-Agriculture Machinery

-Energy

-Electronics

-construction

-translationem

-Industrial

-Consumer Products

Mittens autem die producta sunt quae premente alta followingcatalogues Auwell hasproduced suppleverunt amplissimi orbem elit. Please click for details imaginibus therelevant. Quaeso consilium, maxime in products non solum pro demonstrationpurpose.

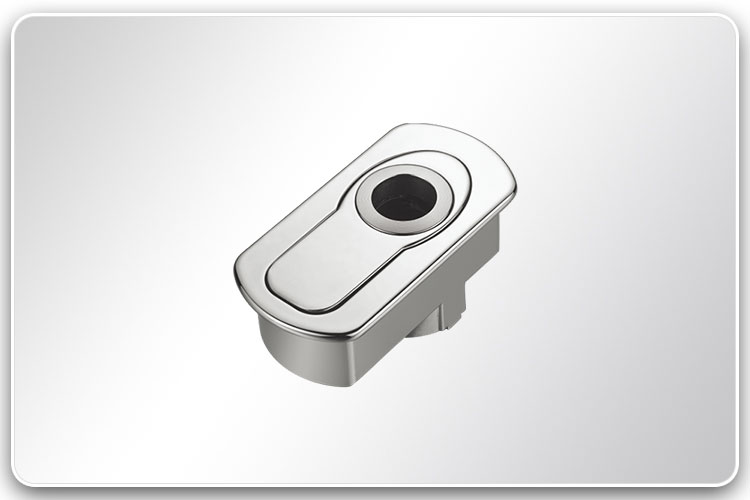

Aluminum Die Casting Music Parts

Aluminum Die Casting Music Parts

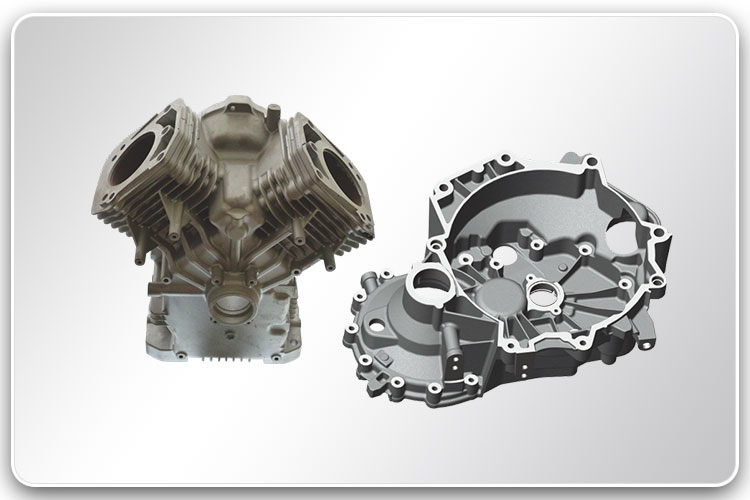

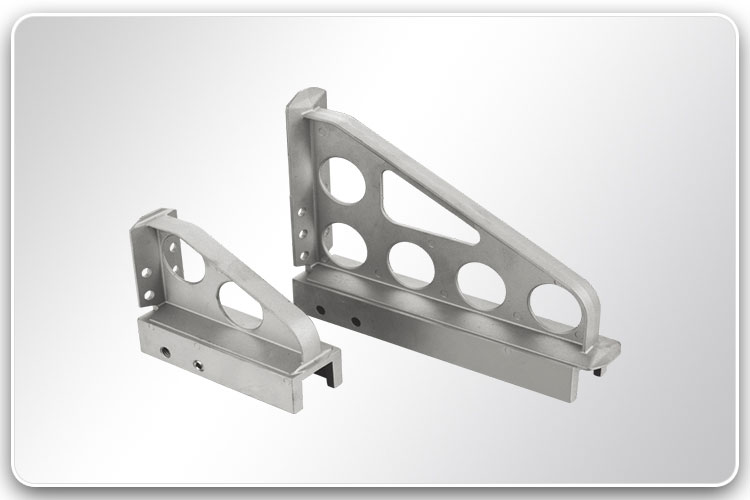

Aluminum Die Casting Industrial Parts

Aluminum Die Casting Industrial Parts

Princeps pressura M. mittentem Tooling

Princeps pressura M. mittentem Tooling

High Pressure Zinc Die Casting Parts

High Pressure Zinc Die Casting Parts

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик