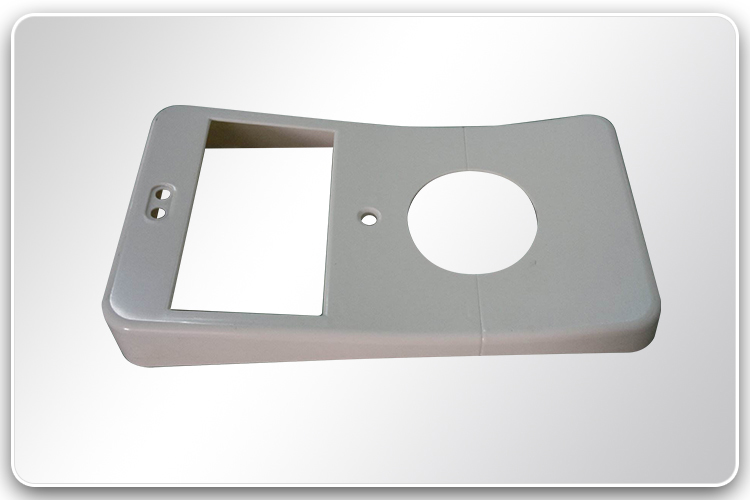

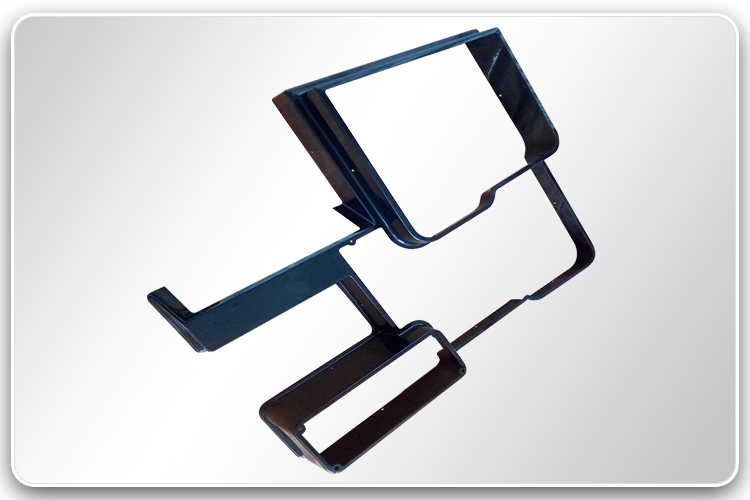

Description

Thermoforming is a manufacturing process whereby a plastic sheet is heated to a pliable forming temperature, formed to a

specific shape in a mold, and trimmed to create a usable product. Auwell has

rich experience in manufacturing and supplying plastic thermoforming parts to

our worldwide clients.

Sunt enim duo genera processus plastic formatam thermoformingparts productionem: et formatam vacuum pressura formatam. FACIUNT CALOREM ET usus pressura vacuum formatam, ad hauriendam plastic laminas in configuratione sua ultima. Cum autem succensa erat sheetis et positus est super fingunt, ea vacuo ad manipulate itsdesired in figura. Formatam multum pressura vacuum in similitudinem formatam, ad buthas additae beneficium of additional pressura. Hoc enim pressura greaterdetail concedit quod velamina filo Sumat facit solidum a in AESTHETICA arbitrium est exitus. Themost ex communi modo est productio Auwell plastic partes thermoforming vacuumforming.

Multa sunt available for use thermoforming plastic partes. Una est morecommon packaging, praecipue propter cibum et rigidas packaging dolor bona, sed etiam multorum aliorum applications comprehendo Automotive habet, machinis, medicalinstruments, alba bona: supellectilem, idoneitatem apparatu etc.

Thermoforming plastic partes productio est relative humilis-sumptus, ut processcompare plastic iniectio, praesertim in tooling sumptus, in aliquibus casibus, non sciri XCV% vilius comparari plastic iniectio formae. Item, cum multa fasterdevelopment circulus. Commonmaterial maxime in plastic partes thermoforming productio est ABS. Si vis ut fieri jubentur bepre colore usus occurrat MOQ (normally1,000kg). Item, Paintable plastic praesto sit, permittens in wide rangeof customization in occursum mos postulo.

Cubits technical

-material

ABSï¼ ASAï¼ PCï¼ PEGTï¼ HDPEï¼ PSï¼ PVCï¼ PMMA

-material Thickness

0.2mm in 8.0mm

Advantages

-Usus rich

More than 20 years of

experience in Plastic thermoforming parts development and part production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Plerumque, providere aquotation in nos operatus III diebus. Combining manufacturingtechnologies et tardus ad facilities, potest eripere Auwell hoc primum specimen in II weeks.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Plastic thermoforming parts development starting

from designing, through prototyping, tooling/fixture development, sampling,

mass production, and to logistic and post-sale support.

-Seu Rigidorum VOL Politiae ipsa QC;

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Plastic thermoforming parts orders. material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Payment termino flexibilia

Nam tooling, generalpayment est terminus est L% -50%, quod est depositum% L, L% Post primum specimenque libero. Formass productio, si termini solucionis offer flexibilior, rationabile willbe credit verbis datum, quod non dat quod hi beati sunt; client cum theyreceived uber. Longa-term projects pro nobis offerre pro muneris vocatio-off inventory fastdelivery requisita.

Related Products

Iniectio plastic Molde pro Automotive Parts

Iniectio plastic Molde pro Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Iniectio plastic Overmolding

Iniectio plastic Overmolding

Rubber & Silicone Molding

Rubber & Silicone Molding

Iniectio partes sequentes catalogi dignissim arethe Auwell quae protulit amplissimi worldwideclients suppleverunt. Please click in imaginibus pertinet ad singula. Quaeso consilium, maxime in products sunt enim modo ad demonstrationem.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик